TM 5-3820-205-10-1

c.

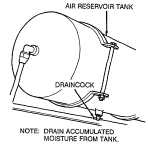

Service the air reservoir (fig. 49).

Figure 49. Air system reservoir service.

Section X. EXHAUST SYSTEM

64.

General

The exhaust system consists of a exhaust silencer and exhaust pipe.

65.

Inspection

Inspect the exhaust silencer and exhaust pipe for cracks or holes. Check for loose exhaust silencer clamps. Ensure

that there are no restrictions in the exhaust silencer or exhaust pipe (i.e., rust, debris).

Section XI. ENGINE CLUTCH ASSEMBLY

66.

General

The engine clutch assembly engages and disengages the power from the diesel engine to the crusher roll drive belts.

67.

Engine Clutch Assembly

a.

Inspect the engine clutch assembly for cracks and loose bolts or engagement handles. The clutch should engage

within four seconds (with engine running). Adjustment may be required if engagement takes longer. If adjustment is

required, notify organizational maintenance.

b.

Service the clutch by following the lubrication instructions on the data plate located at the top of the clutch

SECTION XII. ROLL CRUSHER ASSEMBLY

68.

General

The crusher rolls must be adjusted when the screens are replaced to obtain the desired grade of aggregate. The roll

crusher assembly consists of a smooth roll and a grooved roll for crushing stone. It has a spring on each side to allow

the smooth roll to move beyond its adjusted clearance to allow tramp iron and other items to pass through the rolls that

would otherwise damage the crusher rolls. An adjusting screw, located on each side to adjust the clearance between the

crusher rolls, aids in obtaining the desired grade of aggregate.

69.

Crusher Rolls Adjustment

Note: In making a roll adjustment the sealing surface for the O-rings will be changed. In some cases it may

require several hours of operation before the O-rings seat properly against the seal plate and the oil stops

leaking. A leak of 2-3 qts of oil in eight hours is not considered excessive (gearcase capacity is 92 qt) as

compared to the cost of replacing the O-rings. Furthermore, the O-rings are not designed as a positive type

seal but are designed to allow seepage which will lubricate the Wrings and prevent dust from entering the

gearcase. The oil level of the gearcase should be checked each day. Refer to LO 5-3820-205-12-1.

Adjust the crusher rolls in the numerical sequence as instructed on figure 50.

TA507907

47