TM 5-3820-205-10-2

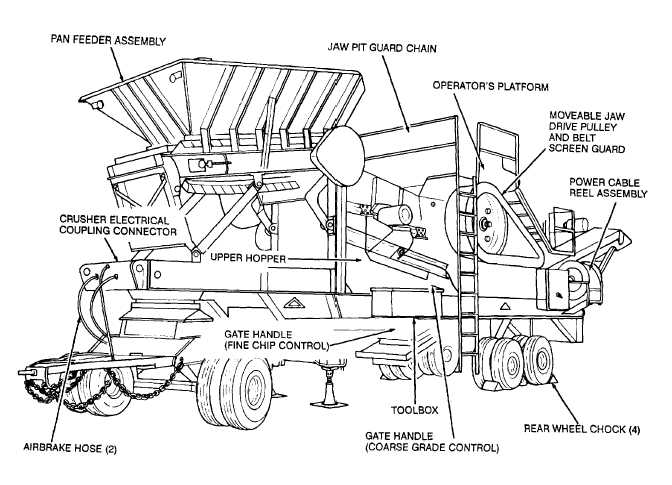

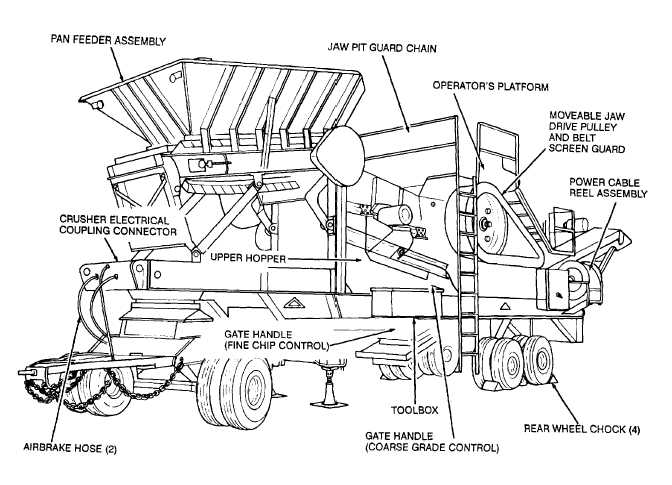

Figure 1. Jaw crsuher, left front, three-quarter view.

4.

Aggregate Crushing and Screening Plant

The jaw crushers illustrated on figures 1 and 2 may be a component of a crushing and screening plant. The plant must

be set up on firm level ground and as near as possible to the source of material to be processed and positioned so the

conveyors may expel the processed aggregate to the desired location for stockpiling or hauling. Figure 3 illustrates a

typical crushing and screening plant layout where the jaw crusher may be utilized as a component. The positions of the

various components may be changed as required. For example, only the final discharge conveyor is absolutely

necessary to operation; the remaining three components indicated are illustrated only where the conveyors could be used

at the discretion of the operator and crew. The power source can be either a generator set that will meet the

requirements or powerline current. The direction of flow of the aggregate processed is also shown on figure 3.

5.

Identification and Tabulated Data

a. Identification. The jaw crusher has 12 identification and instruction plates.

(1)

Corps of Engineers data plate. Located on the left front of the jaw crusher frame. Provides the

description, serial number, manufacturer, model, and dimensions of the jaw crusher.

(2)

Engine identification plate. Located on the left side of the engine. Provides manufacturer, model, and

serial number.

(3)

Transportation data plate. Located on the left front of the jaw crusher frame. Provides center of gravity,

bogie weight, and axle weight.

(4)

Power take off clutch identification and instruction data plate. Located on top of the power takeoff housing

at the rear of the engine. Provides the manufacturer, model, serial number, operation, adjustment, and

lubrication instructions.

TA507923

2