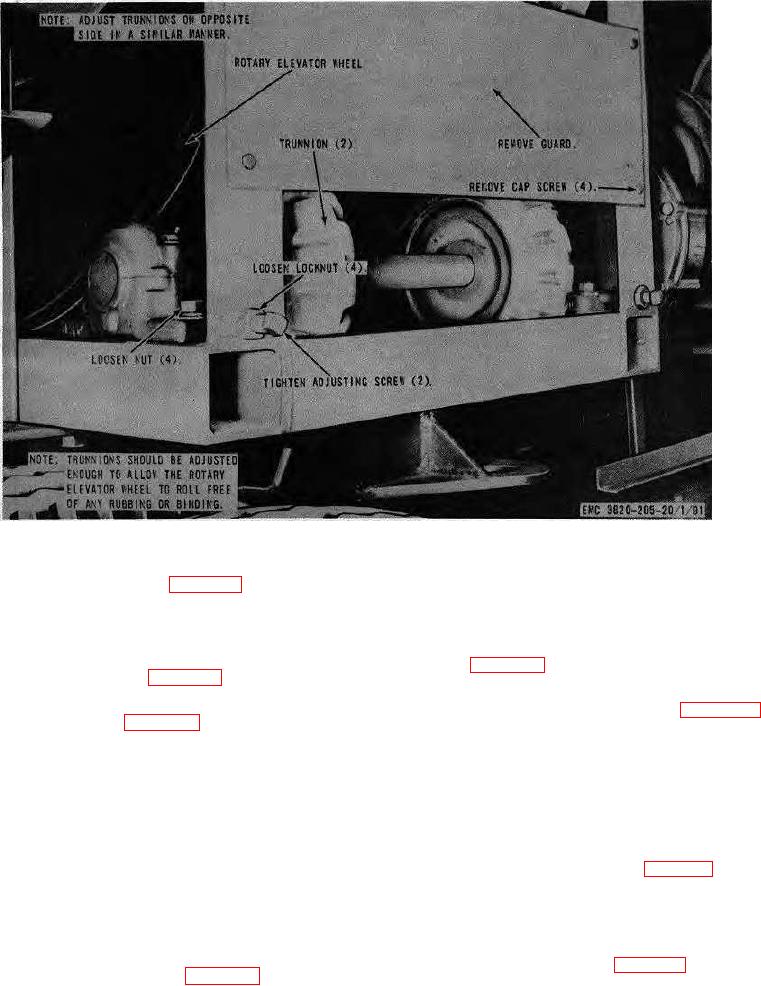

Figure 96. Elevator wheel trunnion and guard adjustment, removal and installation .

(2) Install the ladders (para. 172).

c. Cleaning, Inspection, and Repair. Clean and

inspect all parts. Replace or repair all defective or

damaged parts.

174. Pintle Hook Assembly

d. Reassembly.

Reassemble the pintle hook

a. Removal. Remove the pintle hook assembly

illustrated on figure 111.

from the unit as instructed on figure 110.

e. Installation. Install the pintle hook assembly on

b. Disassembly.

Disassemble the pintle hook

the unit in reverse of the instructions on figure 110.

assembly as illustrated on figure 111.

Section XII. REAR WHEELS, TIRES, AND BRAKES

175. General

b. Cleaning, Inspection, and Repair. Clean and

inspect wheels and tires. Replace defective wheels and

The rear wheels, tires, and brakes consist of

tires. Repair tires as instructed in TM 9-1870-1.

wheels, tires, hub, slack adjusters, and brake

c. Installation. Install the wheels (para. 111).

assemblies. The wheels are dual-type and separated by

a spacer. The assembly is secured to the hub and

177. Wheel Hub Assembly and Brakedrum

brakedrum.

a. Removal.

176. Wheels and Tires

(1) Remove the wheels (para. 111).

a. Removal. Remove wheels (para. 111).

AGO 8157A

129