CHAPTER 7

SHIPMENT AND LIMITED STORAGE

Section I. SHIPMENT WITHIN ZONE OF INTERIOR

185. Preparation of Roll Crusher for Shipment

(3) If the level of coolant is low, add a

mixture of 50 percent water and 50

a. General.

Detailed instructions for the

percent

antifreeze

conforming

to

preparation of the roll crusher for domestic shipment are

Specification O-A-548 type 1, until coolant

outlined within this paragraph. Preservation will be

reaches proper level.

accomplished in sequence that will not require the

operation of previously preserved components.

(4) If temperatures below -250 F.

are

expected, drain the cooling system and fill

b. Inspection. The roll crusher will be inspected for

it

with

antifreeze

conforming

to

any unusual conditions such as damage, rusting,

Specification MILC-11775 in its undiluted

accumulation of water, and pilferage. Inspection will be

condition.

completed as outlined on the quarterly preventive

maintenance services. All deficiencies will be recorded

on DA Form 2404 (Equipment Inspection and

Maintenance Worksheet).

c. Cleaning and Drying. Cleaning the roll crusher

will be accomplished in accordance with an approved

procedure. Approved methods of cleaning and drying,

types of preservatives, and methods of application are

described in TM 38-230.

d. Painting. Paint all surfaces when the paint has

been removed or damaged. Refer to TB ENG 60 for

detailed cleaning and painting instructions.

e. Depreservation Guide.

DA Form 2258

(Depreservation Guide of Engineer Equipment). A

properly annotated depreservation guide will be

completed concurrently with preservation for each item

of mechanical equipment with any peculiar requirements

outlined in blank spaces 27 through 33. The completed

depreservation guide will be placed in a waterproof

envelope, marked "Depreservation Guide," and fastened

in a conspicuous location on or near the operator's

control.

f. Cooling System.

(1) Check the cooling system to determine

the level and protection of the antifreeze

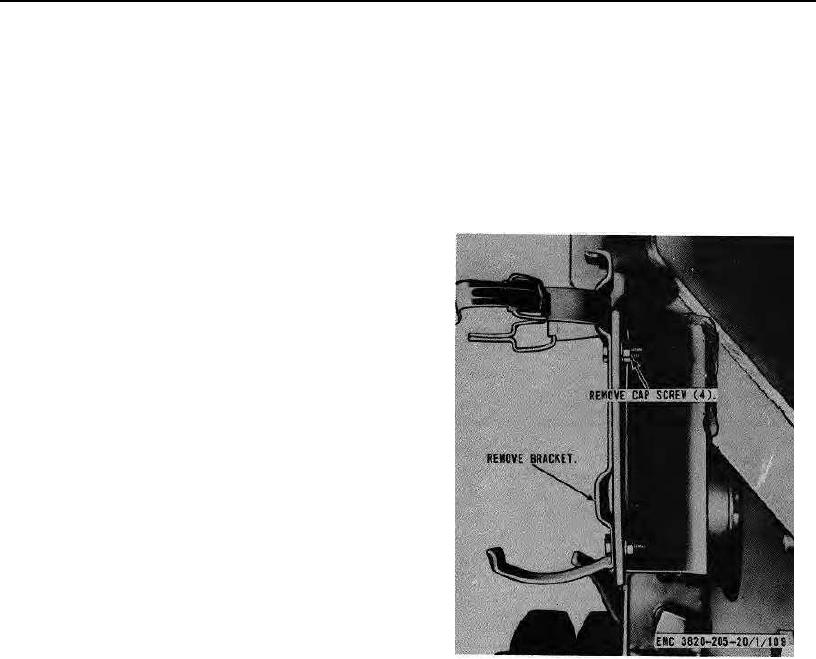

Figure 116. Fire extinguisher bracket, removal and

coolant.

installation.

(2) If the solution is clean and checks at -25

F., it is not necessary to drain and clean

the system.

AGO 8157A

150