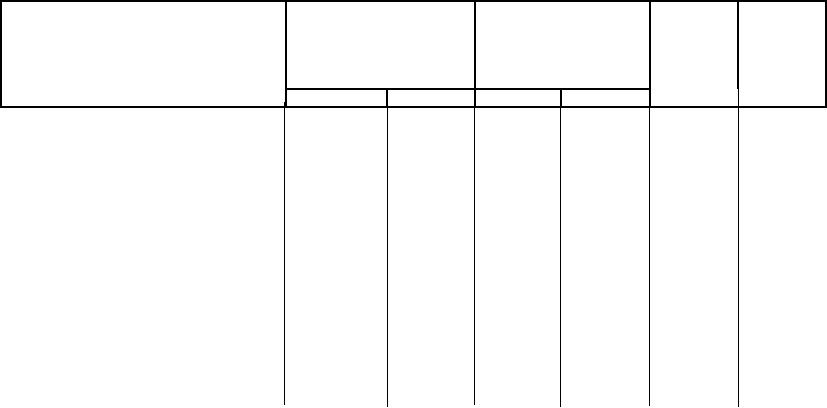

Table 1. Time Standard Continued

Location and service

Man/Hours

Removal and Replacement

Man/Hours

7563

SHAFTS

7528 SCREENS AND ATTACHING

Shaft assemblies (pitman out of

PARTS

unit)

Screen assembly, vibrating

(includes removal and installation

(includes removal and installation

of seals, sleeve nuts, bearings.).. 9.2

of guard and belts, lowering of

Bearings and seals (pitman out of

feeder assembly, and rubber

unit)

mounting.) ...................................... 10.0

(includes removal and installation

Screens

of sleeve nuts and adapter. sleeve.) 3.1

(includes removal and installation

Wheel, balance

of rubber deflector.) .......................... 3.0

(includes removal and installation

Bar, grizzley ......................................... 0.2

of platforms, ladders, framework,

7529 ECCENTRIC OR GYRATOR SHAFT

main drive belts, and guard.)........... 8.5

Shaft assembly

7525

SCREENING BASE, BOX

(includes removal and installation

Box; plates

of guard and belts, pulley,

(includes removal and installation

balance wheels, seals, plates and

of guards and belts, rubber

bearings.) ..................................... 7.8

mounts, grizzley bars, shaft

Bearings

assembly, liners, braces and

(includes removal and installation

crossmembers.) ....................... 19.7

of guard and belts, pulley, balance

Rail, center and crossmember, feed

wheels, seals, and plates.) ........... 7.3

(includes removal and installation

Guard and pulley .............................. 0.7

of screen, grizzley bars, and

Wheel, balance ................................. 1.7

longitudinal bars.) ...................... 4.8

76

FIRE FIGHTING EQUIPMENT

Mounting, rubber ............................ 0.5

7603 FIRE EXTINGUISHER

Deflector, rubber ............................ 0.4

Extinguisher, fire ............................... 0.2

Underhopper

(includes removal and installation

of diverter box.) ......................... 8.0

Box, divert; chute; gate .................. 2.0

clearances, and the maximum allowable wear and

m.

Engine Repair and Replacement Standards.

clearances for the Jaw Crusher.

Table 2

lists manufacturer's sizes, tolerances,

Table 2. Engine Repair and Replacement Standards.

Desired

Maximum

Maximum

Manufacturer's

clearance

allowable

allowable

dimensions and

wear

clearance

tolerance in

inches

Minimum

Maximum

Minimum

Maximum

Valve Guide

Length

Intake ............................................................................. ........... 4.718

Exhaust ....................................................................... ........... 3.812

Outside diameter .................................................. 0.8755......... 0.8765

Stem hole diameter ..................................

Intake................................................................. 0.4985......... 0.4990 ...................... ..................... ......... 0.0020

Exhaust ............................................................. 0.4985......... 0.4995 ...................... ..................... ......... 0.0020

Distance-cylinder head contact face to

top of guide

Intake .......................................................................... ........... 2.000

Exhaust ....................................................................... ........... 2.875

Valves Intake

Length .................................................................. 8.3785......... 8.3995

Stem diameter....................................................... 0.4969......... 0.4977

Head diameter ........................................................2.322........... 2.832

AGO 8456

11