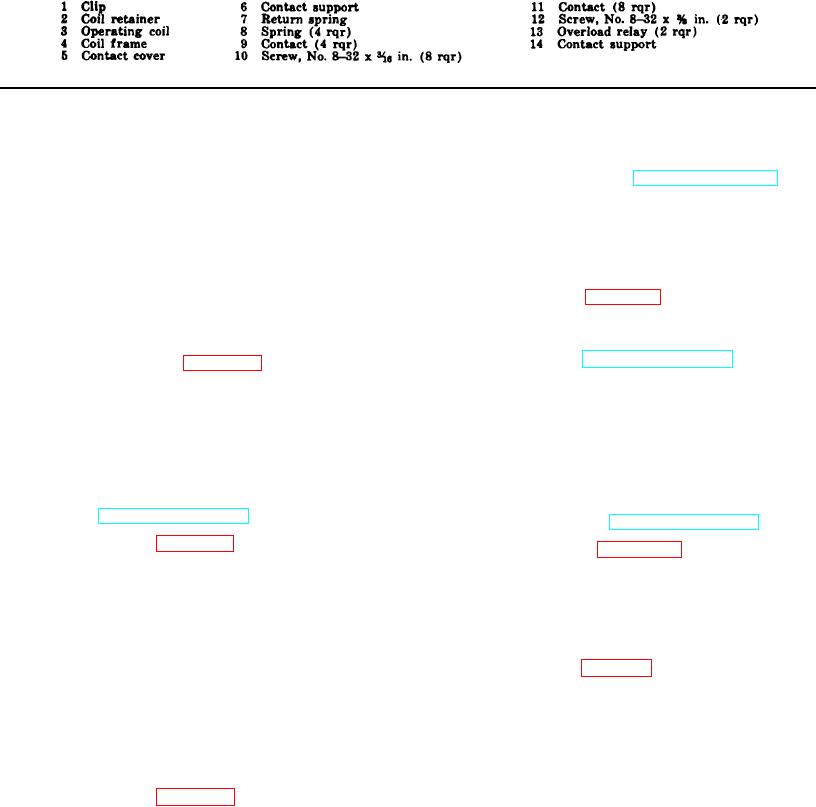

Figure 62-Continued.

Section II. CONTROL PANEL ASSEMBLIES

217. General

(2) Connect all wiring. Refer to tags and

wiring diagram (TM 5-3820-20520/2).

The main control panel assembly contains the

magnetic starter assemblies, circuit breaker, relays,

(3) Install the magnetic starter assemblies

switches, junction blocks, and wiring necessary for

and pushbutton switches (TM 5-3820-205-

controlling the power supply for the various components

20/2).

of the jaw crusher. It is of steel construction and has

b. Installation.

seals around the panel door so it is watertight when

closed. The operator's control panel contains the start

(1) Refer to figure 63 and install the main

and stop switches for the crusher components.

control panel on the unit.

218. Main Control Panel Removal and Disassembly

(2) Position and connect the electric motors

conduit (TM 5-3820-205-20/2).

a. Removal. Refer to figure 63 and remove the

main control panel from the unit.

221. Operator's

Control

Box

Removal

and

Disassembly

b. Disassembly.

a. Removal.

(1) Remove the magnetic starter assemblies

and pushbutton switches (TM 5-3820-205-

(1) Remove the electric conduit (TM 5-3820-

20/2).

205-20/2).

(2) Disconnect and tag all wiring and cables

(2) Disconnect the wiring in the operator's

control box (TM 5-3820-205-20/2).

(3) Refer to figure 64 and disassemble the

(3) Refer to figure 65 and remove the

main control panel.

operator's control box from the unit.

219. Main Control Panel Cleaning, Inspection, and

b. Disassembly.

Repair

(1) Remove the pushbutton switches (TM 5-

a. Cleaning. Clean all parts with an approved

3820-205-20/2).

cleaning solvent and dry thoroughly.

(2) Refer to figure 64 (2) and disassemble the

b. Inspection and Repair. Inspect all parts for wear

operator's control panel.

and damage. Repair or replace as necessary.

222. Operator's Control Box Cleaning, Inspection,

220. Main

Control

Panel

Reassembly

and

and Repair

Installation

a. Cleaning. Clean all parts with an approved

a. Reassembly.

cleaning solvent and dry thoroughly.

(1) Refer to figure 64 and reassemble the

b. Inspection and Repair. Inspect all parts for wear

main control panel in reverse order.

and damage. Repair or replace as necessary.

AGO 3456A

117