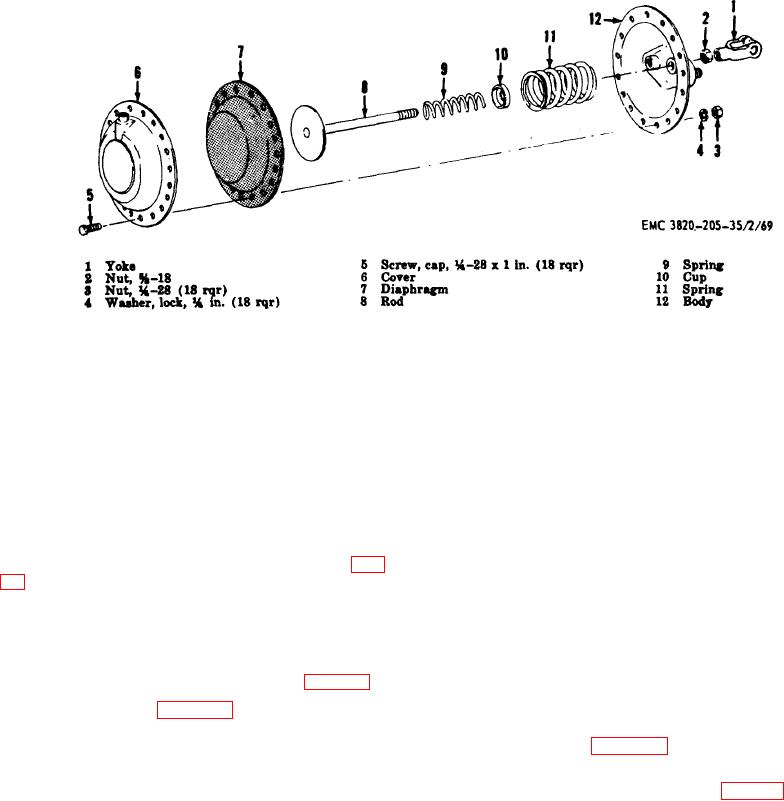

Figure 60. Air chamber assembly, exploded view.

Section II. FRONT AND REAR AXLE ASSEMBLY

b. Inspection and Repair.

206. General

The rear axle assembly consists of two axles, two

(1) Inspect the walking beams for cracks,

walking beams, a center axle and the necessary

breaks, or bends, repair or replace as

hardware to complete the rear axle assembly. The front

necessary.

axle assembly is located under the dolly and fifth wheel

(2) Inspect the axle for bends, wear, or other

assembly. The front axle assembly consists of wheels

damage, replace a bent or defective axle

and axle and supports the front of the crusher.

as necessary.

207. Rear Axle Assembly Removal and Disassembly

(3) Inspect the bushings, clamps, and

a. Removal. Remove the rear axle assembly (par.

clamping ring for excessive wear or

damage. Replace as necessary.

b. Disassembly.

(4) Inspect all mounting hardware for stripped

or damaged threads or other damage,

(1) Remove the air chamber assemblies (TM

replace all damaged parts as necessary.

5-820-206-20/2).

209. Rear Axle

Assembly

Reassembly

and

(2) Remove the brake assemblies (par. 197).

Installation

(3) Refer to figure 61 and disassemble the

a. Reassembly.

rear axle assembly.

(1) Refer to figure 61 and reassemble the

208. Rear Axle Assembly Cleaning, Inspection, and

rear axle assembly in the reverse order.

Repair

(2) Install the brake assemblies (par. 199).

a. Cleaning. Clean all parts with an approved

cleaning

solvent

and

dry

thoroughly.

(3) Install the air chamber assemblies (TM 5-

3820-205-20/2).

AGO 3456A

112