TM 5-3820-233-12/1

CHAPTER 1

INTRODUCTION

Section I. GENERAL

2028 (Recommended Changes to Publications) and

1-1. Scope

forwarded direct to Commanding General, U.S. Army

a. These instructions are published for the use of the

Mobility Equipment Command, ATTN: AMSME-MPP,

personnel to whom the primary crusher jaw unit is

4300 Goodfellow Boulevard, St. Louis Mo. 63120.

issued. They provide information on the operation and

e. Report all equipment improvement recom-

organizational maintenance of the equipment. Also

mendations as prescribed by TM 38-750.

included are descriptions of main units and their

functions in relationship to other components.

b. Refer to TM 740-90-1 (Administrative Storage of

1-2. Record and Report Forms

a. DA Form 2258 (Depreservation Guide for Engineer

Equipment), for information and instructions pertaining to

Equipment).

organizational administrative storage.

c. Refer to TM 750-244-3 (Procedures for Destruction

b. For other record and report forms applicable to

of Equipment to Prevent Enemy Use), for information

operator, crew and organizational maintenance, refer to

and instructions on destruction of equipment to prevent

TM 38-70.

enemy use.

d. Report errors, omissions, and recommendations for

improving this publication by the individual user in

encouraged. Reports should be submitted on DA Form

II. DESCRIPTION AND DATA

determine the right and left side of the plant, stand at

1-3. Description

rear of unit looking forward.

a. The model 2A-2A jaw crusher plant coupled with the

1-4. Difference Between Models

crushing and screening plant provides a complete self

contained and highly mobile crushing and screening unit

The manual covers only the Iowa Manufacturing Co.

capable of producing material under the most severe

Model 2A-2A jaw crusher. No known unit differences

conditions.

b. The plant is used for the production of crushed rock

exist for the model covered by this manual.

and gravel to surface, maintain and repair military roads.

c. The unit consists of a feeder hopper, reciprocating

1-5. Identification and Data

feeder, jaw crusher, delivery conveyor and a diesel

a. Identification. The primary jaw crusher plant has 4

power unit.

d. The unit is trailer mounted using 16.5 x 22.5, 16 ply

major identification plates. The location of these plates

tires with air controlled brakes on all wheels. The rear

are listed in table 1-1.

wheels are mounted on tandem oscillating beams with a

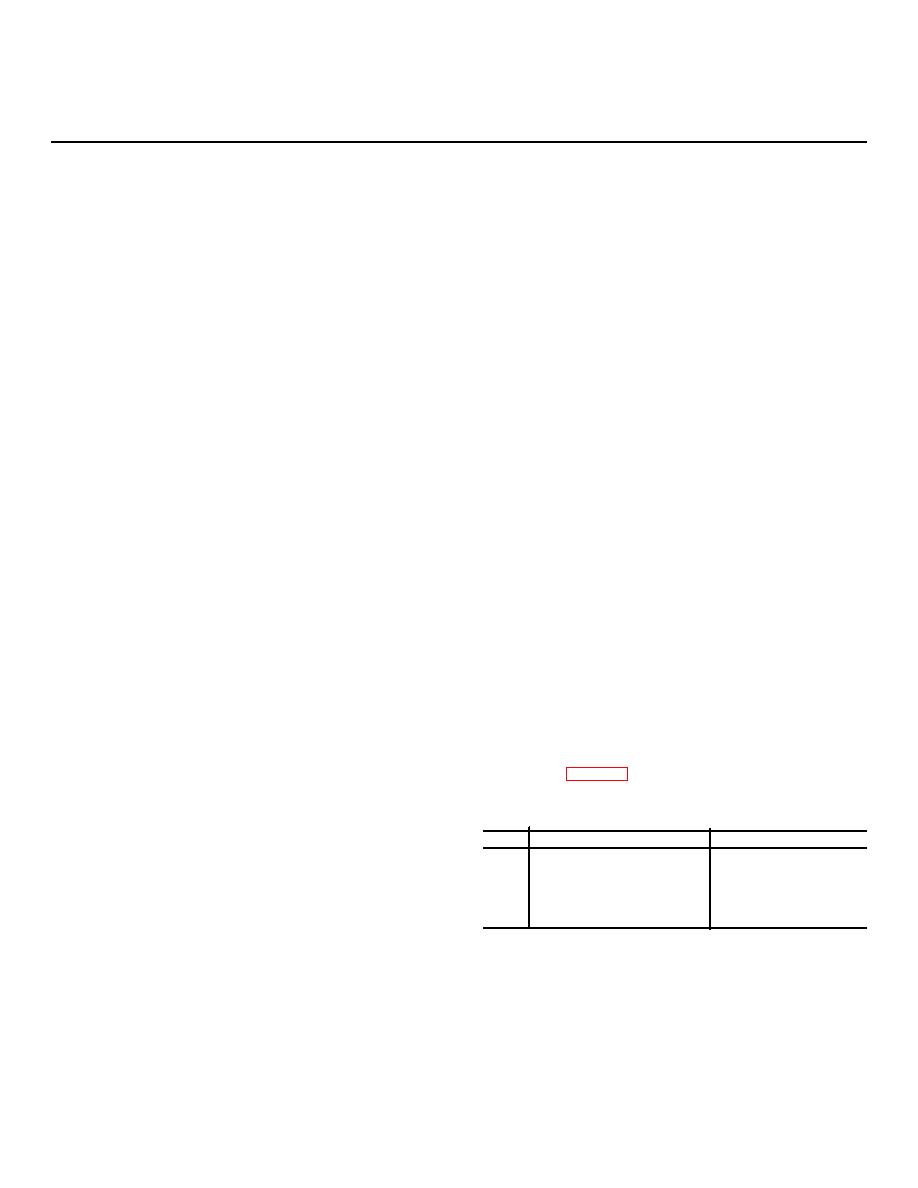

Table 1-1. Information Plates

ridged main axle. The jaw crusher is provided with a

removable dolly, furnished with safety marker lamps,

Item

Description

Location

both service and blackout, and reflectors. The dolly is

fitted with coupling sockets and connecting cable to

1

Plate, identification

Frame, right side

receive electric current for the lamps from the prime

2

Plate, tie down data

Frame, Right side

mover. Clutches for the plant are controlled by the

3

Plate, warning (feeder)

feeder, frame, left side

operator from the walkway. In this manual right and left

4

Plate, battery cable hookup

Frame, right side

will vary. Right and left on the jaw crusher will be

determined by facing the adjusting spring and on

conveyors by facing the direction of material flow. To

1-1