TM 5-3820-233-12/1

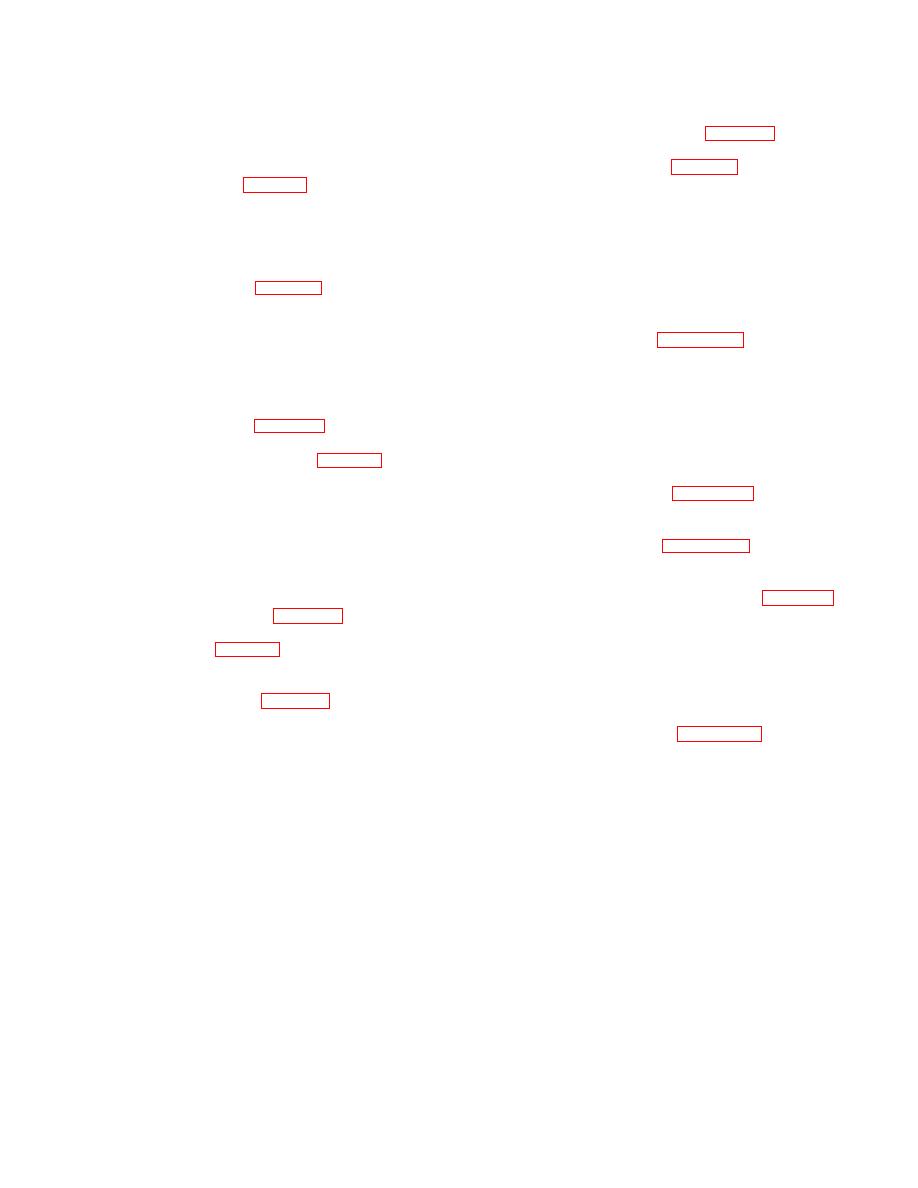

4-89. Crusher Plant Air Brake System

4-93. Air Brake System Filters

a. Removal.

The crusher plant air brake system consists of reservoir,

air brake chamber, relay emergency valve and air filter.

(1) Drain air from air system (para 4-85).

(2) Disconnect tubing from filter.

4-90. Air Reservoir

(3) Remove U-bolt (10, fig. 4-82) and remove filter

a. Removal.

(9).

(1) Open drain cock (40, fig. 4-82) and drain air from

b. Inspection.

system.

(1) Remove cover and inspect strainer, replace if an

(2) Disconnect tubing (19) from elbow (33).

oil substance is present.

(3) Remove bracket (37) and remove the air

(2) Install a new gasket under cover, and replace

reservoir (38).

strainer.

b. Inspection.

c. Installation. Install the air filter in the reverse order

(1) Inspect reservoir (38, fig. 4-82) for holes dents

of removal.

and corrosion.

4-94. Air Line, Hoses and Fittings

(2) Inspect plug (39), elbow (33) and drain cock (40)

for corrosion or damaged threads. Replace defective

a. Removal. Refer to figure 4-82 and remove line,

part or reservoir.

hoses and fittings.

c. Installation. Install in the reverse order of removal.

b. Inspection.

(1) Inspect hoses and lines for cracks, breaks and

4-91. Brake Chamber

kinks.

a. Removal.

(2) Inspect fittings for breaks, damaged threads and

(1) Bleed air from system (para 4-90).

worn or damaged gaskets.

(2) Disconnect air line from brake chamber.

(3) Check for leakage in drain cocks and couplings.

(3) Remove the brake chamber (27, fig. 4-79).

Replace a defective part.

b. Inspection. Inspect the brake chamber for proper

c. Installation. Refer to figure 4-82 and install lines,

operation and damage. Replace a defective brake

hoses and fittings.

chamber.

c. Installation. Install the brake chamber in the

4-95. Crusher Plant Wiring Harness and Lights

a. Removal. Refer to figure 4-83 and remove the

reverse order of removal.

wiring harness and lights.

b. Inspection.

4-92. Relay Emergency Valve (Air Brake System)

(1) Inspect the wiring harness (5, fig. 4-83) for

a. Removal.

deterioration and cuts.

(1) Drain air from air system (para 4-85).

(2) Inspect the lamps (8, 22, 24 and 27) for loose

(2) Disconnect all hoses, lines and fittings.

connections, corrosion, rust and cracked or broken lens.

(3) Remove nut (29, fig. 4-82) washer (30), bolt (31)

(3) Inspect the lamp supports (25 and 26) for

and remove the relay emergency valve (32) from frame.

damage.

b. Inspection.

(4) Inspect the reflectors (20) for cracked lens.

(1) Inspect the elbow (20, fig. 4-82) and connector

Replace all defective parts or lights.

(21) for stripped threads.

c. Installation. Refer to figure 4-83 and install the

(2) Inspect the valve (32) for damage. Replace

wiring harness and lights.

defective valve.

c. Installation. Install the relay emergency valve in

the reverse order of removal.

4-88