TM 5-3820-233-35/1

(2) Refer to figure 7-3 and disassemble

between the commutator bars or other causes

the starter.

which would prevent good contact between

the brushes and commutator.

e. Cleaning

(f) Low no-load speed and low cur-

(1) The drive, armature and fields

rent draw indicate a high internal resistance

should not be cleaned in any degreasing tank,

due to poor connections, defective leads, dirty

or with grease dissolving solvents, since these

commutator and causes listed under (e).

would dissolve the lubricant in the drive and

(g) High free speed and high current

damage the insulation in the armature and

draw indicate shorted fields.

field coils. All parts except the drive should

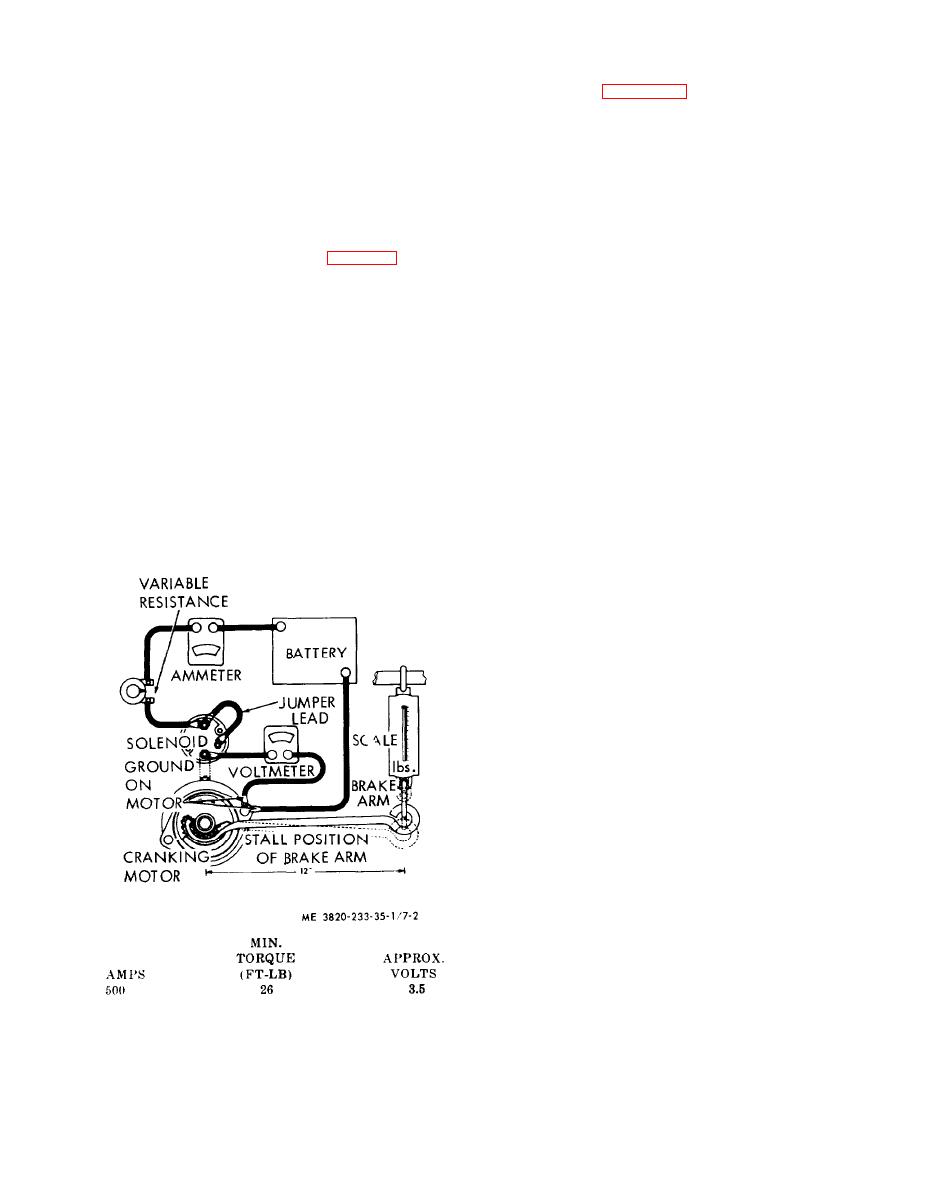

(3) Lock-Torque Test (fig. 7-2). The

be cleaned with oleum spirits and a brush.

lock-torque test requires the equipment il-

The drive can be wiped with a clean cloth.

lustrated. A variable resistance with a high

(2) If the commutator is dirty it may be

current capacity should be used. The cranking

cleaned with No. 00 sandpaper. NEVER USE

motor should be SECURELY mounted and a

EMERY CLOTH TO CLEAN COMMUTA-

brake arm hooked to the drive. When speci-

TOR.

fied current is applied, the torque can be

f. Inspection and Repair

computed from the reading on the scale. A

(1) Inspect housings and frames for

one foot brake arm will directly indicate foot-

cracks a n d d i s t o r t i o n . I n s p e c t t h r e a d s i n

pound. If the torque is low, the motor must

tapped holes for damage. Replace defective

be disassembled for further tests and repair.

parts.

d. Disassembly

(2) Inspect sleeve bearings for wear. Re-

(1) Scribe marks across drive housing,

place bearing if defective. Check for looseness

fever housing, frame and end ball to facilitate

in housing or end bell. Replace worn or de-

reassembly in the correct relationship.

fective bearings. If new bearing is loose in

bore, replace housing or end bell.

(3) Inspect wicks for tests, fraying, or

wear. Replace if defective.

(4) Turn down commutator if grooved

or out of round. Undercut mica to a depth

of 0.025 to 0.032 inch below surface of com-

mutator. Do not widen slots when undercut-

ting mica.

(5) Inspect drive pinion for broken or

badly worn teeth. Inspect clutch splines for

wear and damage. Inspect shell for cracked

or broken condition. Check to make sure pin-

ion will drive into one direction and will slip

in opposite direction. Replace drive clutch if

defective.

(6) Inspect shift lever, shaft, and sole-

noid plunger for cracks or distortion. Replace

defective parts.

(7) Inspect bellows for tears, punctures,

and deterioration.

or other damage. Replace if defective.

(9) Inspect brushes for wear or damage.

If damaged, or worn excessively, replace them.

g. Testing

(1) To test armature for grounds or

short, refer to TM 5-764.

3-2