TM 5-3820-233-35/1

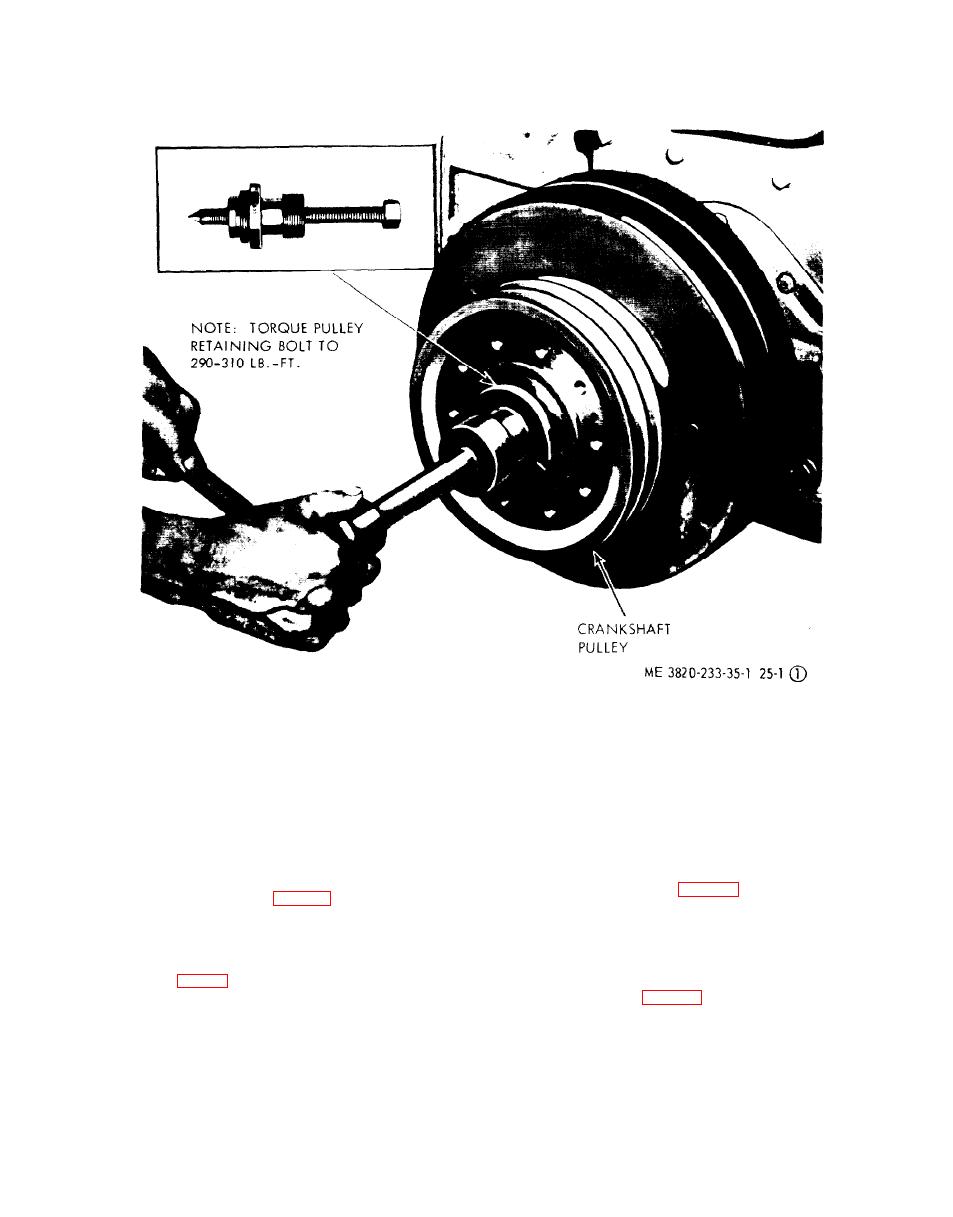

STEP 1. REMOVE CRANK SHAFT PULLEY.

Figure 25-1 (1). Crankshaft pulley and front cover, removal and installation.

(2) Perform a magnetic inspection on the

(5) Inspect main bearings for wear,

crankshaft for cracks, breaks, or indications of

roughness, and overheating. Replace defective

fatigue. Replace the crankshaft if any of the

above mentioned conditions exist.

(6) Check runout of crankshaft journals.

Refer to table 1 for correct tolerance and

(3) Measure the main bearing and con-

clearance data. If the runout limit is greater

necting rod journals for wear and out-of-

than the data given in table 1, replace the

roundness. Refer to table 1 for tolerance and

crankshaft.

clearance data.

(7) Inspect oil pump drive gear and

(4) Inspect the thrust washers for wear

crankshaft timing gear for chipped or cracked

or roughness. Measure washer thickness. Re-

teeth. Replace a defective gear.

fer to table 1 for correct dimensions and tol-

(8) Measure journal-to-bearing shell

erance data. Replace defective washers.

clearence. Refer to table 1 for allowable tol-

3-45