3208 INDUSTRAIL AND MARINE ENGINES

DISASSEMBLY AND ASSEMLBLY

CRANKSHAFT AND GEAR

9.

Remove the bearing caps and measure the

thickness of the wire.

The main bearing

clearance must be .002 to .005 in. (0.05 to 0.13

mm). The maximum permissible clearance is

.006 in. (0.15 mm).

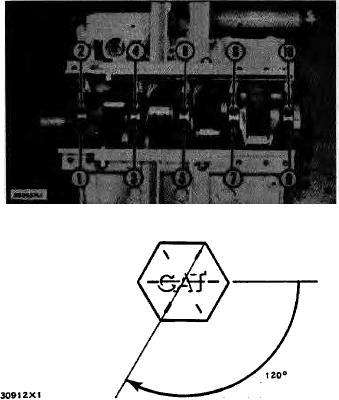

10. Put clean engine oil on the bolt threads, washer

faces and lower halves of the main bearings.

Put the bearing caps in position and install the

bolts. Tighten the bolts in number order as

follows:

a)

Tighten bolts 1 through 10 to a torque of 30

3 lb. ft. (4.1 0.4 mkg).

b)

Put a mark on each bolt head and bearing

cap. Tighten bolts I through 10 120 5

more.

11. Install indicator group (A) and check the end

play of the crankshaft.

The end play is

controlled by the thrust bearing on No. 4 main

bearing. The end play with new bearings must

be .006 .003 in. (0.15 0.08 mm). The

maximum permissible end play with used

bearings is .014 in. (0.36 mm).

end by:

a) install

timing gear cover and oil pump

b) install

c) install

valve lifters

d) install

flywheel housing

94