AXLES:

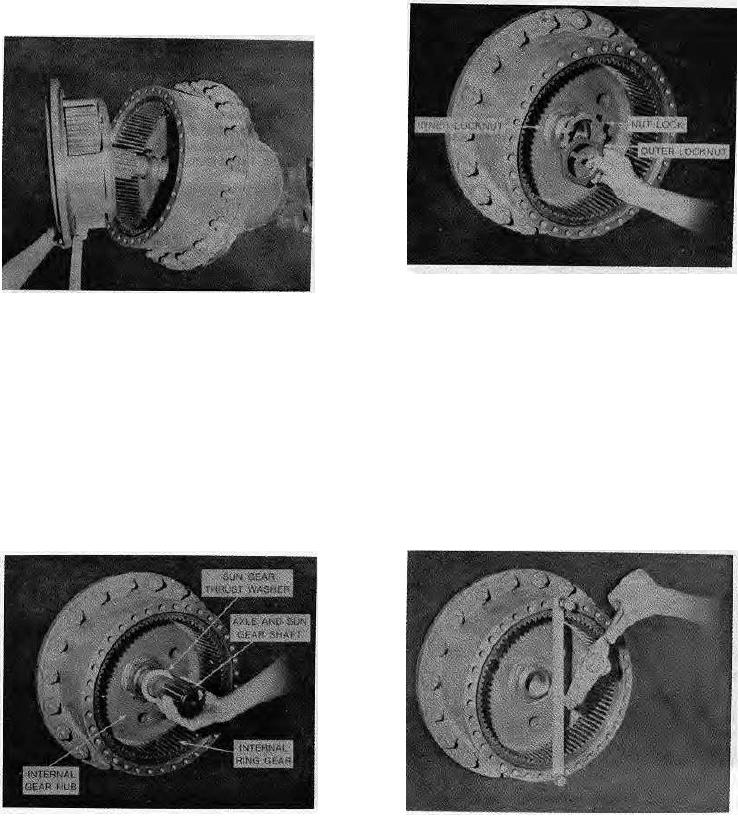

7. Remove planet carrier from hub assembly.

12. Tighten wrench guide screws lightly against shim stock

and remove outside spindle nut and lock ring.

Removing Planetary Carrier

13. Check rolling torque of hub assembly by attaching

torque wrench adapter bar across face of hub assembly

8. Remove sun gear retaining ring and pull off sun

and attach torque wrench to center of bar.

gear.

14. Attach a 50 ft-lb (7 m-kg) torque wrench and check

9. Remove sun gear thrust ring from spindle end.

rolling resistance of wheel hub. Rolling resistance when

using new bearing should be 15 to 20 ft-lbs (2,0 to 2,8 m-

10. Straighten tangs on outer lock nut.

kg). On used bearings, the rolling resistance should be 6 to

12 ft-lbs (0,8 t 1, 7 m-kg).

11. Wrap shim stock around end of axle shaft to

protect shaft splines and install special wrench (PN

954940) on outside spindle nut.

Checking Torque

K300

Rev. 760501

50-3.2