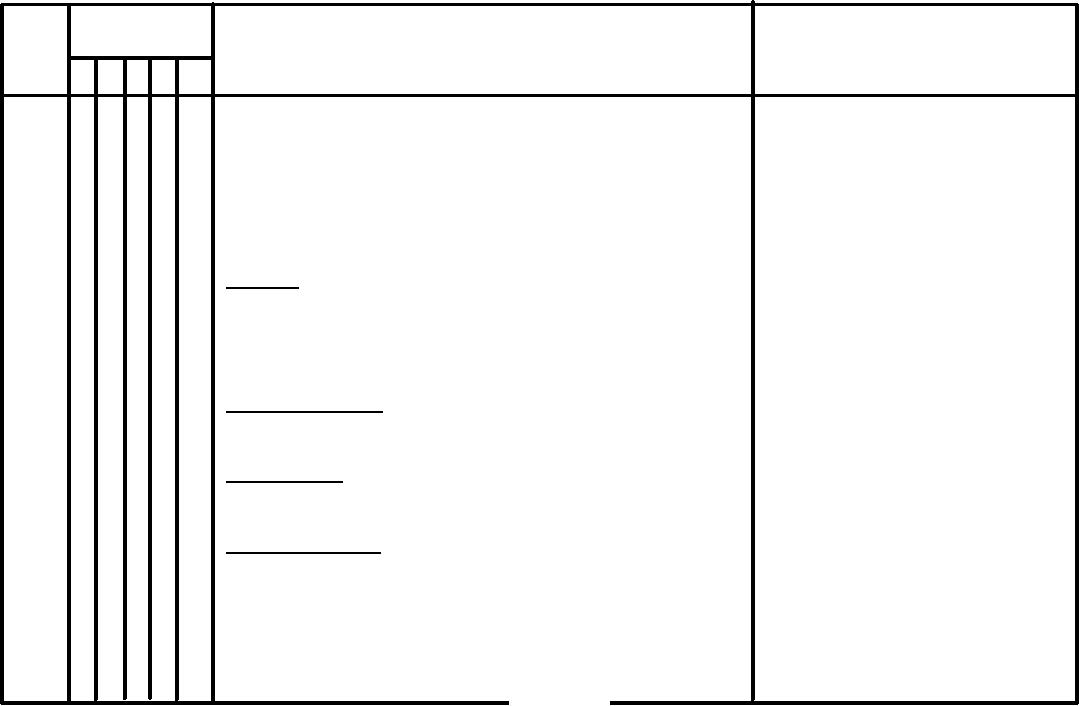

OPERATOR/CREW PREVENTIVE MAINTENANCE CHECKS AND SERVICES

BBefore

DDuring

AAfter

WWeekly

MMonthly

ITEMS TO BE INSPECTED

INTERVAL

PROCEDURE: Check for and have repaired, filled or

Equipment is not ready/

ITEM

adjusted as needed.

AVAILABLE IF:

NO.

DMQ

A

AR

NOTE

PERFORM WEEKLY AS WELL AS BEFORE PMCS's IF:

a.

You are the assigned operator but have not operated

equipment since the last weekly.

b.

You are operating the equipment for the first time.

1

GENERAL

a.

Visually check for loose wiring, 4ds wed piping or hoses.

b.

Look for evidence of fluid leakage (oil, fuel, coolant).

Class III leaks or any fuel

leakages found.

2

ENGINE CRANKCASE

Check dipstick for proper level. Add oil, as necessary, to

Full mark. (At operating temperature, engine idling, 180-200 F).

3

TRANSMISSION

Check dipstick for proper level. Add oil, as necessary, to

Full mark (At operating temperature, engine idling, 180-200 F).

4

HYDRAULIC SYSTEM

a. Check hydraulic tank level sight gage (blade lowered and

engine off). Add oil as required.

b. Check hoses and connections for condition and leaks.

Class III leaks found.

39