TM 5-3820-205-10-1

CHAPTER 2

INSTALLATION AND OPERATION INSTRUCTIONS

Section I. SERVICE UPON RECEIPT

7. Unloading the Roll Crusher

The operator may assist in unloading the roll crusher from the common carrier. The operator will help

remove the tie-down cables, strapping, blocking, etc. which secure the roll crusher on the carrier.

Organizational maintenance will perform the remaining operations.

8. Inspecting and Servicing Equipment

Note: Ensure that the roll crusher is completely deprocessed before servicing. Ensure that

preservatives have been removed from such items as crankcase, fuel tank, and gearboxes.

a. Perform the Operator/Crew Preventive Maintenance Checks and Services (para 32).

b. Make a complete visual inspection to see that required tools, repair parts, publications, accessories, and

attachments are with the roll crusher and are in serviceable condition.

c. Visually inspect the roll crusher for loss of parts or damage which may have occurred during loading,

shipping, or unloading.

d. Report all damage and deficiencies to organizational maintenance.

e. Refer to Table 1 for a complete list of the maintenance and operating supplies required for initial operation of

the roll crusher.

9. Installation or Setting-Up Instructions

a. Locate the roll crusher on a flat or leveled surface. If necessary, use any suitable equipment such as a

bulldozer to level the site. Plan the site so there will be no obstruction to trucks or other hauling vehicles going

to and from the plant. Refer to figure 3 for suggested placement of plant components. After the roll crusher is

located, level the area immediately under the roll crusher frame for cribbing.

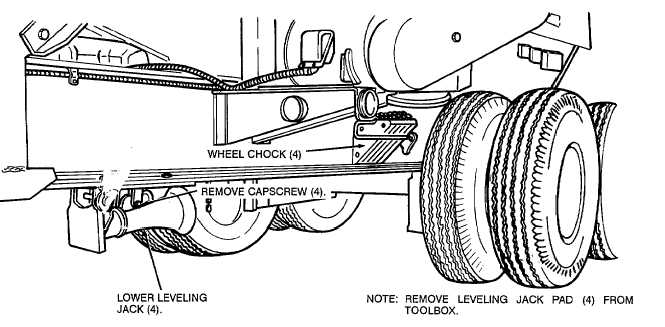

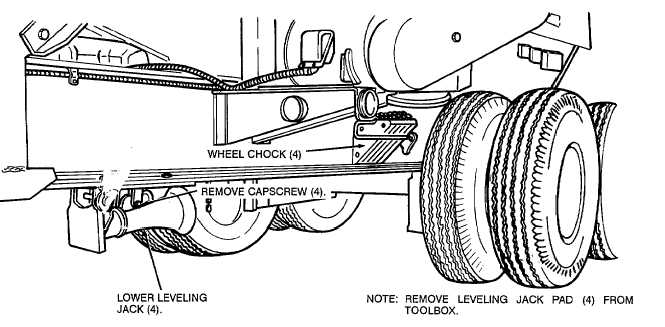

b. Remove the wheel chocks (fig. 4) from their brackets on the main frame above the rear wheels and securely

block the rear wheels (fig. 5).

Figure 4. Leveling jacks and wheel chocks, stowed position.

TA507879

7