TM 5-3820-205-10-1

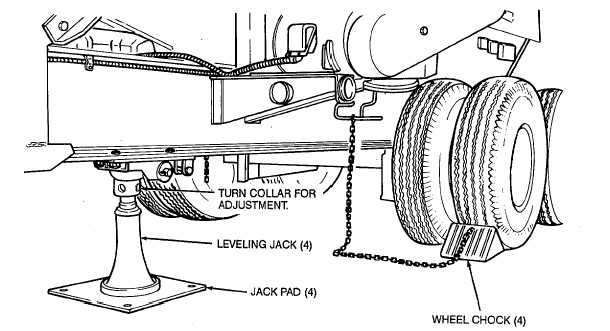

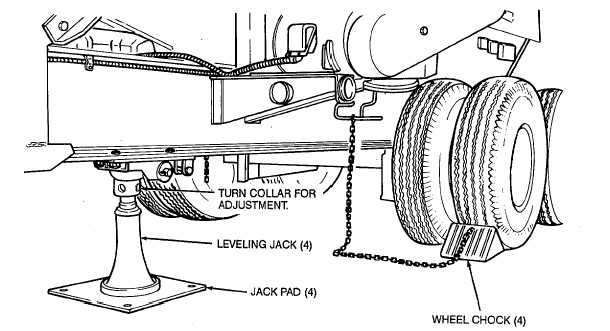

Figure 5. Leveling jacks and wheel chocks installed position.

c. The roll crusher is equipped with four mounted screw-type leveling jacks. Lower the leveling jacks (fig. 4) and

position the jacks into the jack pad recess (fig. 4). If the ground is soft or provides a poor bearing surface, place

timbers or other suitable supports under the jack pads.

Caution: Install the leveling jacks and cribbing so that roll crusher will be level both lengthwise

and crosswise, and the weight of the roll crusher is removed from the wheels and axles. Inaccurate

leveling may cause the drive belts and conveyor belts to run off, material to travel to one side of

screens, and rubber mountings of the vibrating screen to twist, resulting in damage to equipment.

d. Level the trailer frame. Check in several places to avoid having a twist or sag in the frame. Adjust the jacks

accordingly. Accuracy in leveling is very important, because an improperly leveled roll crusher unit may

cause the drive belts and conveyor belts to run off, material to travel to one side of screens, and rubber

mountings of the vibrating screen to twist.

e. Crib the roll crusher by raising the front end with the leveling jacks, keeping the crusher level, and build the

cribbing solidly up to the frame. Screw the leveling jacks back a few turns, allowing the weight to rest on the

cribbing. Crib under the rear end of the roll crusher frame in a similar manner.

f. Remove the drawbar jack from stowed position (fig. 6). Install the drawbar jack (fig. 7) (on units of equipment

within serial number range 6590 through 6629).

g. Position the discharge conveyor of the crushing and screening plant (fig. 3).

Warning: Do not connect electrical power or operate the equipment if the ground connection is

not properly in. stalled (fig. 8). Death by electrocution could result from improperly grounded

equipment.

h. Install the ground rod (fig. 8).

i. Remove the main power cable and the feeder jumper cable from their reels (figs. 9 and 10).

TA507880

9