TM 5-3820-205-10-2

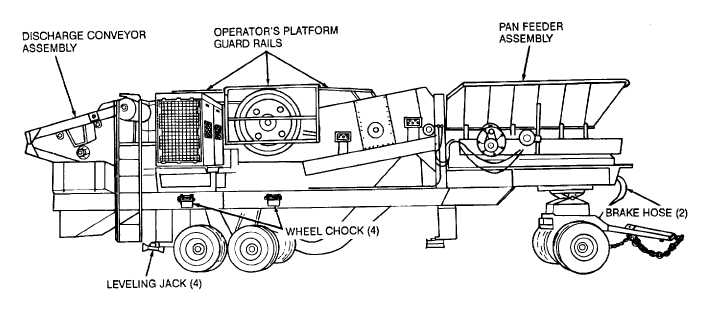

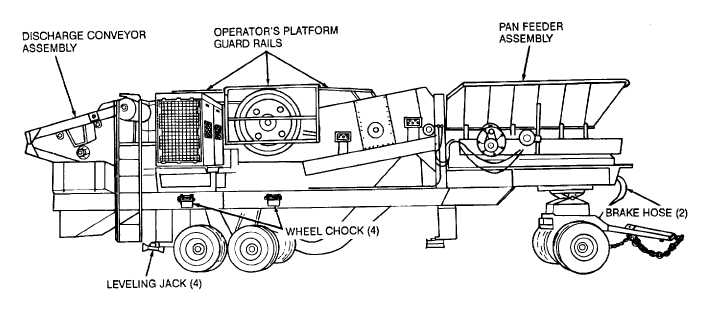

Figure 18. Jaw crusher prepared for transport.

g.

Raise and secure the leveling jacks in transport position in reverse of the instructions on figure 4, and stow jack

pads in the toolbox.

h.

Remove jaw crusher electric cable connector and airbrake hoses from the toolbox and install on jaw crusher (fig.

1).

Caution: Do not exceed 20 mph on good hard surface road or 10 mph on secondary roads or cross-country

when towing the jaw crusher.

i.

Attach suitable towing vehicle to the jaw crusher. Remove the wheel chock (fig. 1) and stow them in the bracket

on the frame (fig. 18).

j.

If the movement of the new worksite is a short distance and the equipment could be safely towed over existing

roads and bridges with sufficient safe clearances, it is not necessary to perform all of the above operations for

transporting the jaw crusher to its new worksite. Follow the instructions in subparagraphs a, b, c, g, h, and i for this type

of movement.

k.

Install and set-up the jaw crusher (para 9).

Section II. CONTROLS AND INSTRUMENTS

11. General

This section describes, locates, illustrates, and furnishes the operator or crew sufficient information about the

various controls and instruments for proper operation of the jaw crusher.

12. Controls and Instruments

Caution: Operator's switch boxes must be properly closed and sealed to prevent water from entering the box

and causing switches and controls to corrode and become unserviceable. All control boxes should be

examined to assure that doors are properly sealed and closed tight.

The purpose, location, and use of the controls and normal readings of the instruments and gages are illustrated on

figures 19-29.

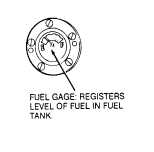

Figure 19. Fuel gage.

18