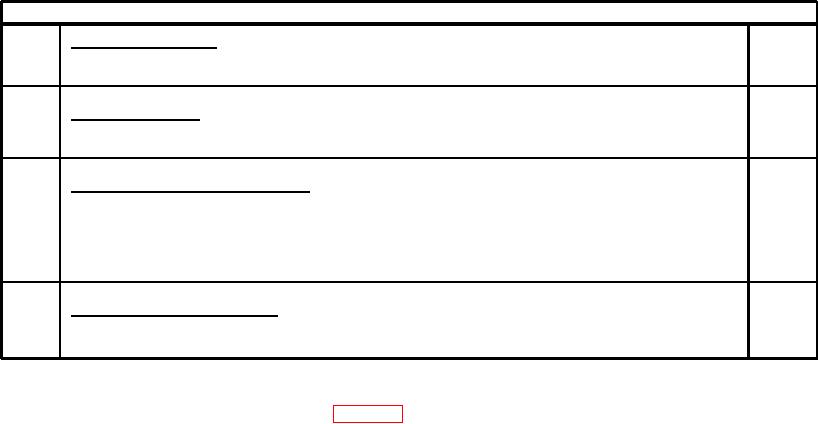

ITEM

PAR. REF

20

VALVE MECHANISM. Check valves every 1000 hours for proper

adjustment. Proper adjustment is 0.020 inch for intake

valves and 0.024 inch for exhaust. (HOT)

21

MASTER CLUTCH. Check for proper operation and adjustment.

Adjust clutch until a firm pressure is required to engage

clutch.

22

CONTROLS AND INSTRUMENTS. Inspect controls and instruments

for damage and loose connections. With the unit operating,

inspect for Improper operation. Normal operating readings

for instruments are as follows: Oil pressure gage - 55 to

65 psi, Water temperature gage - 165 to 185F, Ammeter -

green range, Tachometer - 1,400 rpm.

NOTE. OPERATIONAL TEST. During operation check for

unusual noise or vibration, leaks, and proper

operation.

MSC 3820-205-20/1/4.1

Figure 6-Continued.

AGO 8157A

22