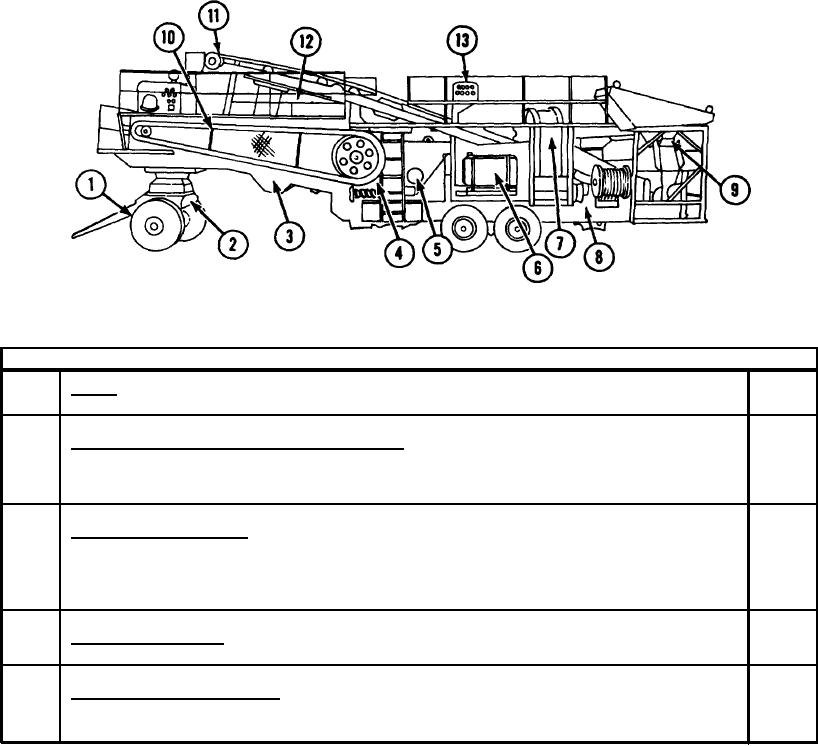

PREVENTIVE MAINTENANCE SERVICES

QUARTERLY

TM 5-3820-205-20/1

ROLL CRUSHER

EAGLE MODEL 5230B

LUBRICATE IN ACCORDANCE WITH CURRENT LUBRICATION ORDER

ITEM

PAR. REF

1

TIRES. Inspect for cuts, wear, and deterioration. Check

pressure. Proper pressure is 100 psi.

2

CRUSHER AND DOLLY ELECTRICAL SYSTEM. Check for deteriorated

or frayed wiring. Check lights for proper operation. Check

motors and Junction boxes for cracks, breaks, and excessive

noises or vibration during operation.

3

HOPPERS AND CHUTES. Check control levers for proper opera-

tion. Check hopper liners for excessive wear. Replace

liners before worn through. Check deflectors for wear and

proper adjustment. When hopper is loaded, deflectors should

barely touch conveyor belt.

4

FIRE EXTINGUISHER. Inspect for full charge by shaking for

sound or by weighing. Check for broken seal.

5

ROLL CRUSHER ASSEMBLY. Check for cracks, breaks, and proper

162

operation. Check tension spring for proper adjustment.

Adjust spring to 23 inches in length.

Figure 6. Quarterly preventive maintenance services.

AGO 8157A

19