Warning: When servicing battery, do not smoke

j. Fill cooling system with proper coolant to protect

or use open flame in the vicinity. Batteries generate

cooling system to lowest temperature expected. For

hydrogen, a highly explosive gas.

cold-weather operation, refer to TM 9-207. Table I lists

the freezing points, composition, and specific gravities

i. Lubricate the roll crusher according to the

of military antifreeze materials.

current lubrication order (LO 5-3820-205-20/1).

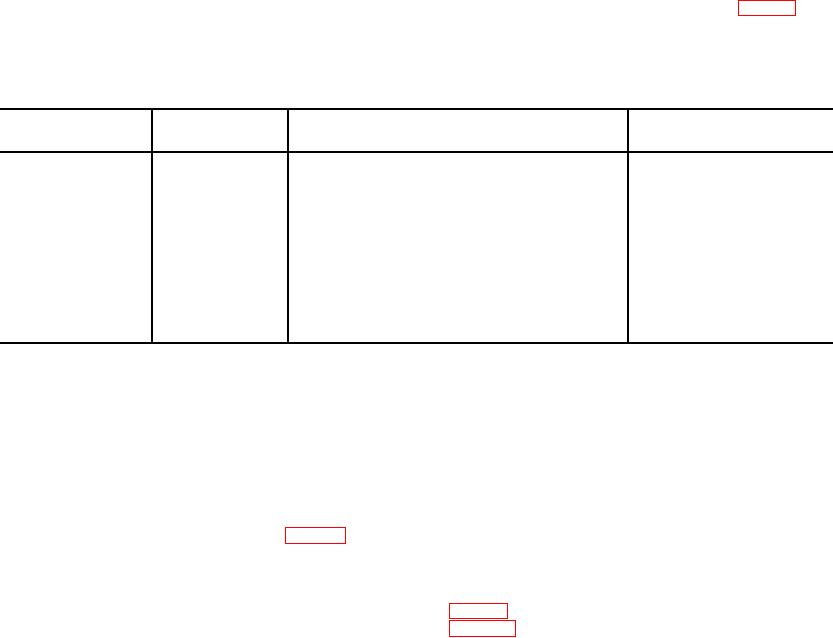

Table I. Freezing Points, Composition, and Specific Gravities of Military Antifreeze Materials.

Lowest expected

Pints of inhibited

Compound, Antifreeze

Ethlylene glycol solution

2

ambient temp

glycol per gal of

Artic

specific gravity at

1

3

F.

Coolant

68F.

+20

1 /12

Issued full strength and ready mixed for 0F. to

1.022

+10

2

-65F. temperatures for both initial installs-

1.036

0

2 3/4

tion and replenishment of losses.

1.047

-10

3 1/4

1.055

-20

3 1/2

1.062

30

4

1.067

-40

4 1/4

1.073

-50

Arctic Anti-

DO NOT DILUTE WITH WATER

-60

freeze

OR ANY OTHER SUBSTANCE.

-75

preferred.

1

Maximum protection is obtained at 60 percent by volume. that is 4.8 pints of ethylene glycol per gallon of solution.

Military Specification MIL-C 11755 Arctic type, nonvolatile antifreeze compound is intended for use in the cooling system of liquid-cooled internal combustion

engines for protection against freezing primarily in Arctic regions where the ambient temperature remains for extended periods of time close to -40F. or drops

below, to a low as -90F.

3

Use an accurate hydrometer. To test hydrometer, use 1 part ethylene glycol antifreeze to 2 parts water. This should produce a hydrometer reading of 0F.

Note. Fasten a tag near the radiator filler cap indicating the types of antifreeze.

k. On new equipment flush the fuel lines and fuel

(10) Stop the engine, remove the plug from

the tee, install the elbow, and connect the

filters as follows:

return fuel line.

(1) Disconnect fuel line from filter at fuel

pump end as instructed on figure 5.

9. Installation of Separately Packed Components

(2) Drain the fuel filter (TM 5-3820-205-10/1).

a. Install the fire extinguisher in the bracket on the

right side of the roll crusher.

(3) Flush fuel lines and filters by operating

the primer pump (TM 5-3820-205-10/1).

b. Unpack and depreserve the battery cables

(para. 7). Install the battery cables on the batteries

(4) Connect fuel line at fuel pump.

(5) Disconnect fuel lines from injectors.

c. Install the necessary sized screens for desired

(6) Operate starter for 30 seconds (TM 5-

operation (TM 5-3820-205-10/1).

3820-205-10/1).

10. Installation or Setting Up Instructions

(7) Connect fuel lines to injectors.

For installation and setting-up instructions, refer

(8) Disconnect the fuel return line, remove

to TM 5-3820-205-10/1.

the elbow, and install a plug in the pipe

tee..

(9) Start the engine (TM 5-3820-20510/1).

AGO 8157A

15