(2) Install the engine housing door supports

c. Installations.

(3) Install the muffler assembly (para. 73).

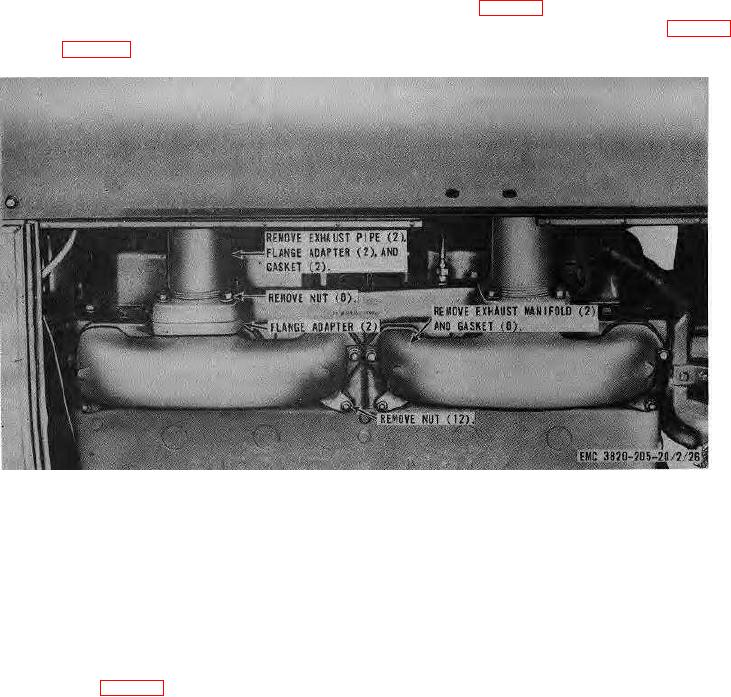

the engine in reverse of the instructions

on figure 26.

Section V. ENGINE ELECTRICAL SYSTEM

75. General

(2) Use a voltmeter to test each cell for

The electrical system of the roll crusher is a 24-volt

voltage. Each full charged cell must

system which consists of four batteries, generator,

deliver two volts. A low voltage indicates

generator regulator, starter, oil pressure gage and

a low charge or a defective cell.

sending unit, water temperature gage and sending unit,

Recharge the batter, if the output voltage

battery indicator gage, safety governor, safety ignition

varies more than 30 percent between

switch, and the necessary wiring and connectors to

cells, replace the battery.

complete the system. Figure 1 is the wiring diagram for

Warning

the roll crusher electrical system.

Do not smoke or allow an open flame

near charging batteries.

Serious

76. Batteries and Cables

injury from explosion and acid could

a. Testing.

result. Avoid spilling electrolyte on

(1) Use a hydrometer to test each battery

clothing or flesh.

Acid causes

cell; each cell should read 1.280 specific

severe burns.

gravity at 80 F. Recharge if the reading is

b. Removal.

1.250 or less.

(1) Loosen locknut (fig, 27) and place clamp

handle up or at right angle to battery

terminal.

AGO 8157A

45