first mile, fifth mile, and tenth mile retorque inner and

(3) Clean and inspect wheels and tires.

then outer nuts to 500 to 600 ft-lb. If at the tenth mile

Replace defective wheels and tires.

torque value has dropped below 400 ft-lb, remove

Repair tires and tubes as instructed in TM

wheels, investigate, and repeat entire procedure.

9-1870-1.

Caution

c. Installation.

A trestle (Motor Vehicle Maintenance,

(1) Install inner wheel on hub.

5 ton) will be used in final torquing

Note. Number the studs 1 to 6.

operations, taking care that drive

(2) Install inner capnuts on studs 1 and 4 and

extensions are parallel to the ground

torque to 150 to 200 ft-lb.

at all times.

(3) Install the remaining capnuts and torque

112. Wheel Bearing and Hub Assemblies

No. 2, 5, 3, and 6 to 500 to 600 ft-lb in

a. Removal and Disassembly.

that order. Retorque Nos.

(1) Remove the dolly wheels (para. 111).

1 and 4 to 500 to 600 ft-lb.

(2) Remove and disassemble wheel bearings

(4) Install the outer wheel assembly, making

as illustrated on figure 57.

sure that the outer wheel valve stem is

b. Cleaning, Inspection, and Repair.

opposite the inner valve stem.

(1) Clean and inspect all parts. Replace

(5) Install two outer nuts on opposite studs

defective parts as necessary.

(without the washers installed) and torque

(2) Service the wheel bearings as instructed

to 150 to 200 ft-lb.

(6) Install the four remaining outer nuts (with

c. Reassembly and Installation.

washers installed) and torque to 500 to

(1) Install the bearings and hub on the axle as

600 ft-lb in the sequence outlined above.

illustrated on figure 57.

(7) Remove the two outer nuts (5 above) and

Note. Install hubs with right-hand studs

reinstall with washers and torque to 500 to

on right side of the vehicle and hubs with

600 ft-lb.

left-hand studs on left side of the vehicle.

(8) Remove the dolly from the blocks using a

(2) Install the wheel bearing adjusting nut.

suitable lifting device and road test

Screw the nut against the bearing as the

approximately 10 miles. After

wheel is revolved. Be sure there is

sufficient

clearance

between

the

brakeshoe and drum so brakeshoe drag

will not interfere with the bearing

adjustment.

(3) Tighten the adjusting nut to 50 ft-lb torque

while the wheel is being rotated. Rotate

the wheel in both directions to position the

bearings correctly.

(4) Back-off adjusting nut 1/6 to 1/4 turn, and

install the adjusting nut lockwasher. If the

holes in lockwasher do not fit dowel

protruding from adjusting nut, the washer

may be removed and turned over, which

changes hole locations.

(5) Install the outer locknut and torque to 250

to 400 ft-lb.

Note. The use of an impact wrench is

discouraged; however, if used, the final

torquing

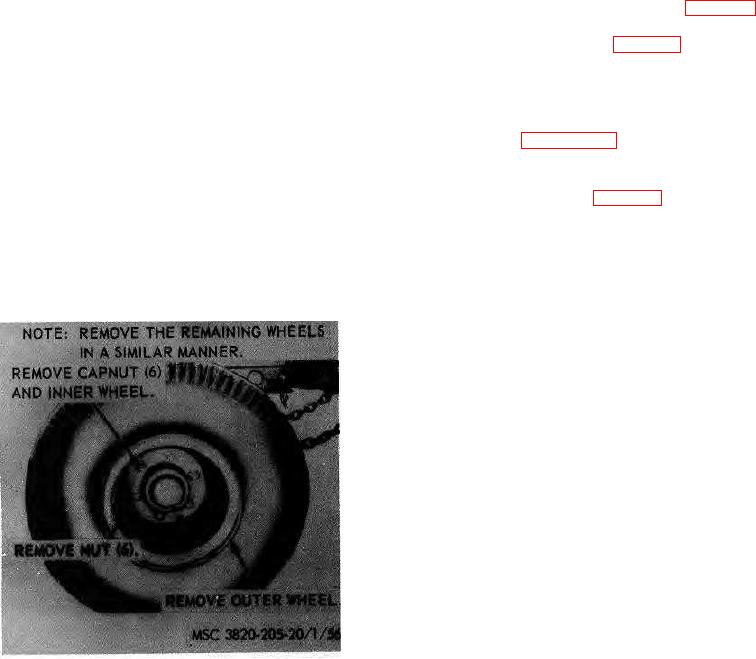

Figure 56. Dolly wheels, removal and installation

AGO 8157A 83