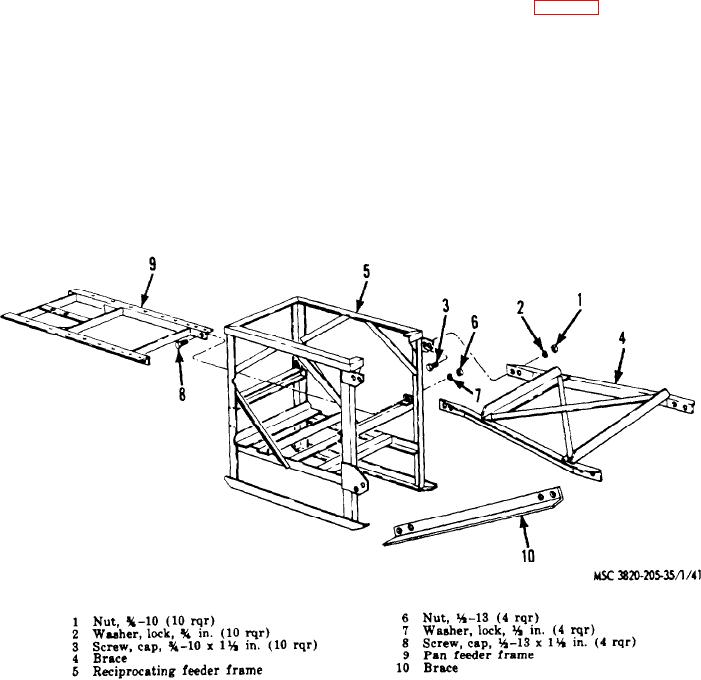

Se c t ion I I I . RECI PROCAT I N G FEEDER FRAM E

(3) Remove the reciprocating feeder gear

125. General

reducer assembly (TM 5-3820-205-

The reciprocating feeder frame supports the

20/l).

r e c i p r o c a t i n g feeder assembly which controls

(4) Remove the reciprocating feeder, drive

t h e flow of material to the roll crusher. The

motor (TM 5-3820-206-20/l).

a s s e m b l y consists of a feeder grizzly, upper

(5) Remove the feeder jumper reel and

h o p p e r , feeder hopper, and reciprocating feeder

bracket assembly (TM 5-3820-205-

p l a t e . The feeder plate moves back and forth

20/l).

i n a reciprocating movement actuated by the

crank-arm drive. The flow of material from

(6) Remove the pan feeder and rollers,

the reciprocating feeder to the crusher is con-

(TM 5-3820-205-20/1).

trolled by an adjustable gate, and a relief chute

b . Disassembly. Refer to figure 41, and dis-

on the left side.

assemble the reciprocating feeder frame.

126. Reciprocating Feeder Frame Removal

127. Reciprocating Feeder Frame Cleaning,

and Disassembly

Inspection, and Repair

a. Removal.

a. Cleaning. Clean all parts with an ap

(1) Remove the reciprocating feeder as-

proved cleaning solvent and dry thoroughly.

s e m b l y (par. 30).

b. Inspection and Repair. Inspect the feeder

( 2 ) Remove the feeder hopper assembly

f r a m e for cracks, breaks, bends, and torn or

(TM 5-3820-205-20/l).

Figure 41. Reciprocating feeder frame, exploded view.

88

AGO 8498A