Section IV. UNDER HOPPER

156. General

The under hopper is made up of chutes, diverter box

and gates which divert different size materials to

different conveyors and outlets.

157. Under Hopper Removal and Disassembly

a. Removal.

(1) Remove the course chute and diverter box

(TM 5-820-205-20/2).

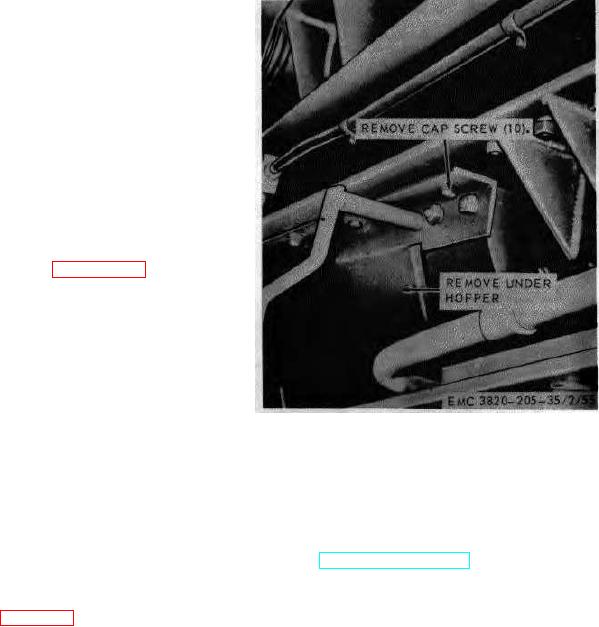

(2) Refer to figure 46 and remove the under

hopper from the unit.

Refer to figure 47 and

b.

Disassembly.

disassemble the under hopper.

158.

Under Hopper Cleaning, Inspection, and

Repair

a. Cleaning. Clean all parts with an approved

cleaning solvent and dry thoroughly.

Figure 46. Under hopper, removal and installation.

b. Inspection and Repair.

b. Installation.

(1) Inspect all parts for cracks, breaks,

warpage, or rusting and repair or replace as

(1) Refer to figure 46 and install the under

necessary.

hopper on the unit.

(2) Inspect all hardware for damaged threads

(2) Install the course chute and diverter box

and replace as necessary.

159. Under Hopper Reassembly and Installation

a. Reassembly. Refer to figure 47 and reassemble

the under hopper in the reverse order.

AGO 8456A

92