1

Nut, 5/8-11 (16 rqr)

29

Lower rail

2

Washer, lock, 5/8 in. (16 rqr)

30

Lower rail

3

Screw, cap, 5/8-11 x 2 in. (16 rqr)

31

Nut, 5/8-11 (4 rqr)

4

Washer, flat, 5/8 in. (16 rqr)

32

Washer, lock, 5/8 in. (4 rqr)

5

Support

33

Screw, cap, 5/8-11 x 1 1/2 in. (4 rqr)

6

Nut, 5/8-11 (16 rqr)

34

Washer, flat, 5/8 in. (8 rqr)

7

Washer, lock, 5/8 in. (16 rqr)

35

Lower support

8

Screw, cap, 5/8-11 x 2 in. (16 rqr)

36

Nut; 5/8-11 (16 rqr)

9

Washer, flat, 5/8 in. (32 rqr)

37

Washer, lock, % in. (16 rqr)

10

Support

38

Screw, cap, 5/8-11 x 2 in. (16 rqr)

11

Nut, 5/8-11 (16 rqr)

39

Washer, flat, 5/8 in. (32 rqr)

12

Washer, lock, 5/8 in. (12 rqr)

40

Crossmember

13

Screw, cap, 5/8-11 x 1 in. (16 rqr.)

41

Nut, 5/8-11 (2 rqr)

14

Washer, flat, 5/8 in. (32 rqr)

42

Washer, lock, 5/8 in. (2 rqr)

15

Plate

43

Screw, cap, 5/8-11 x 1 in. (2 rqr)

16

Deflector plate

44

Washer, flat, 5/8 in. (4 rqr)

17

Plate

45

Clip

18

Deflector plate

46

Nut, -12 (4 rqr)

19

Nut, 5/8-11 (16 rqr)

47

Washer, lock, in. (4 rqr)

20

Washer, lock, 5/8 in. (16 rqr)

48

Screw, cap, 13 x 1I in. (4 rqr)

21

Screw, cap, 5/8-11 x 1% in. (16 rqr)

49

Washer, flat, in. (8 rqr)

22

Washer, flat, 5/8 in. (32 rqr)

50

Brace

23

Upper rail

51

Brace

24

Upper rail

52

Crossmember

25

Nut, 5/8-11 (16 rqr)

53

Crossmember

26

Washer, lock, 5/8 in. (16 rqr)

54

Crossmember

27

Screw, cap, 5/8-11 x 2 in. (16 rqr)

55

Side plate

28

Washer, flat, 5/8 in. (32 rqr)

56

Side plate

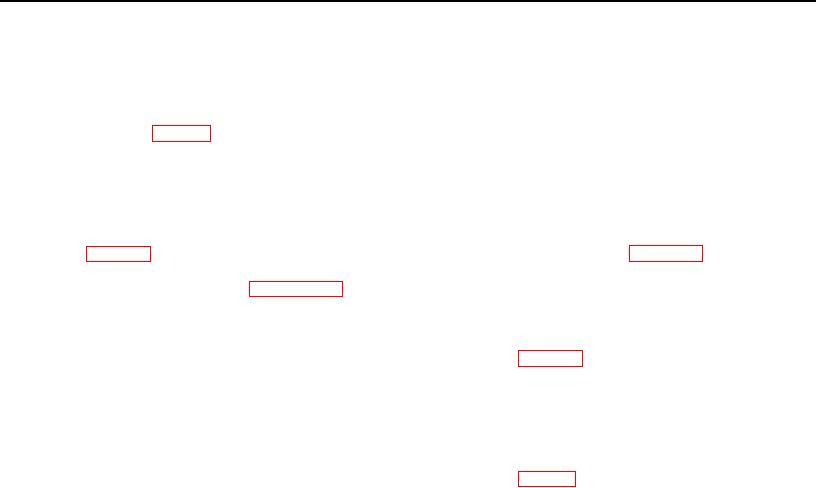

Figure 45-Continued.

elongated holes.

Repair or replace as

153.

Scalper Vibrating Screen Box Assembly

necessary.

Removal and Disassembly

(2) Inspect the support braces, boxes, and

a. Removal.

straps for cracks, breaks, or any other

damage and repair or replace as necessary.

(1) Remove the scalper

vibrating

screen

assembly (par. 32).

(3) Inspect all mounting hardware for damaged

threads and replace as necessary.

(2) Remove the electric drive motor, belts,

drive sheave, and balance wheels (TM 5-

155.

Scalper Vibrating Screen Box Assembly

3820-205-20/2).

Reassembly and Installation

(3) Remove the vibrating mechanism assembly

a. Reassembly. Refer to figure 45 and reassemble

the scalper vibrating screen box in the reverse order.

Refer to figure 45 and

b.

Disassembly.

b. Installation.

disassemble the scalper vibrating screen box assembly.

(1) Install the vibrating mechanism assembly

154.

Scalper Vibrating Screen Box Assembly

Cleaning, Inspection, and Repair

(2) Install the electric drive motor, belts, drive

a. Cleaning. Clean all parts in an approved

sheave, and balance wheels (TM 5-3820-

cleaning solvent and dry thoroughly.

205-20/2).

b. Inspection and Repair.

(3) Install the scalper vibrating screen assembly

(1) Inspect the side plates and reinforcing

plates for cracks, breaks, rusting, or

AGO 8456A

91