162. Pitman Assembly Cleaning, Inspection, and

Repair

a. Cleaning. Clean and inspect all parts in an

approved cleaning solvent and dry thoroughly.

b. Inspection and Repair.

(1) Inspect all seals for wear, nicks, and

deterioration and replace as necessary.

(2) Inspect the split sleeve and locknuts for

breaks, cracks, or damaged threads and

replace as necessary.

(3) Inspect bearings, for cracks, worn rollers, or

any other damage and replace as

necessary.

(4) Inspect all other metal parts for damage and

repair or replace as necessary.

163.

Pitman Assembly Reassembly and

Installation

a. Reassembly. Refer to figure 49 and reassemble

the pitman assembly in the reverse order.

Note. Install the spacers (30, fig. 49(2) and

bearings (29) on the shaft (28) and install

as an assembly in the pitman (31). Make

certain that the shaft is centered in the

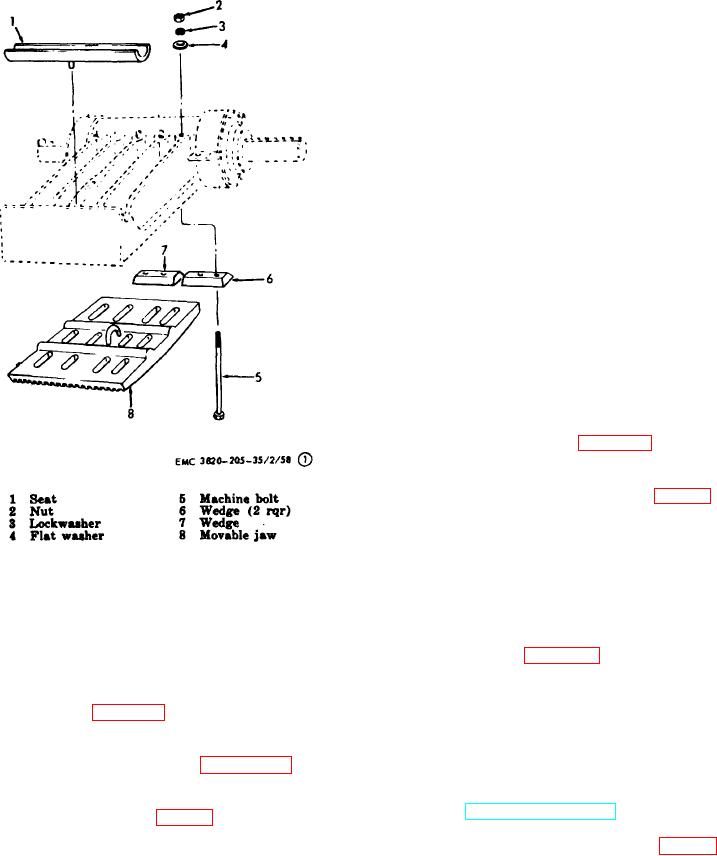

Figure 49. Pitman assembly, exploded view.

movable jaw before securing the

housings and sealers.

(2) Remove the tension spring and rod

assembly (TM 1-38202-20/2).

b. Installation.

(3) Remove the toggle plate from the bottom of

(1) Refer to figure 48 and install the pitman

the crusher assembly by pushing the

assembly on the unit.

movable jaw forward.

(2) Install the toggle plate in the bottom of the

(4) Refer to figure 48 and remove the pitman

crusher assembly by pushing the movable

assembly.

jaw forward and positioning the plate in the

toggle seats.

Refer to figure 49 and

b.

Disassembly.

disassemble the pitman assembly.

(3) Install the tension spring and rod assembly

Note. Remove the shaft (28, fig. 49(2), spacers (30),

and bearings (29) from the pitman as an assembly,

(4) Install the crusher assembly (par. 33).

and remove the bearings and spacers from the

shaft.

(5) Adjust the crusher assembly (TM 5-3820-

205-20/2).

AGO 8456A

95