TM 5-3820-233-12/1

(2) Inspect the cover adaptor (13) for cracks or

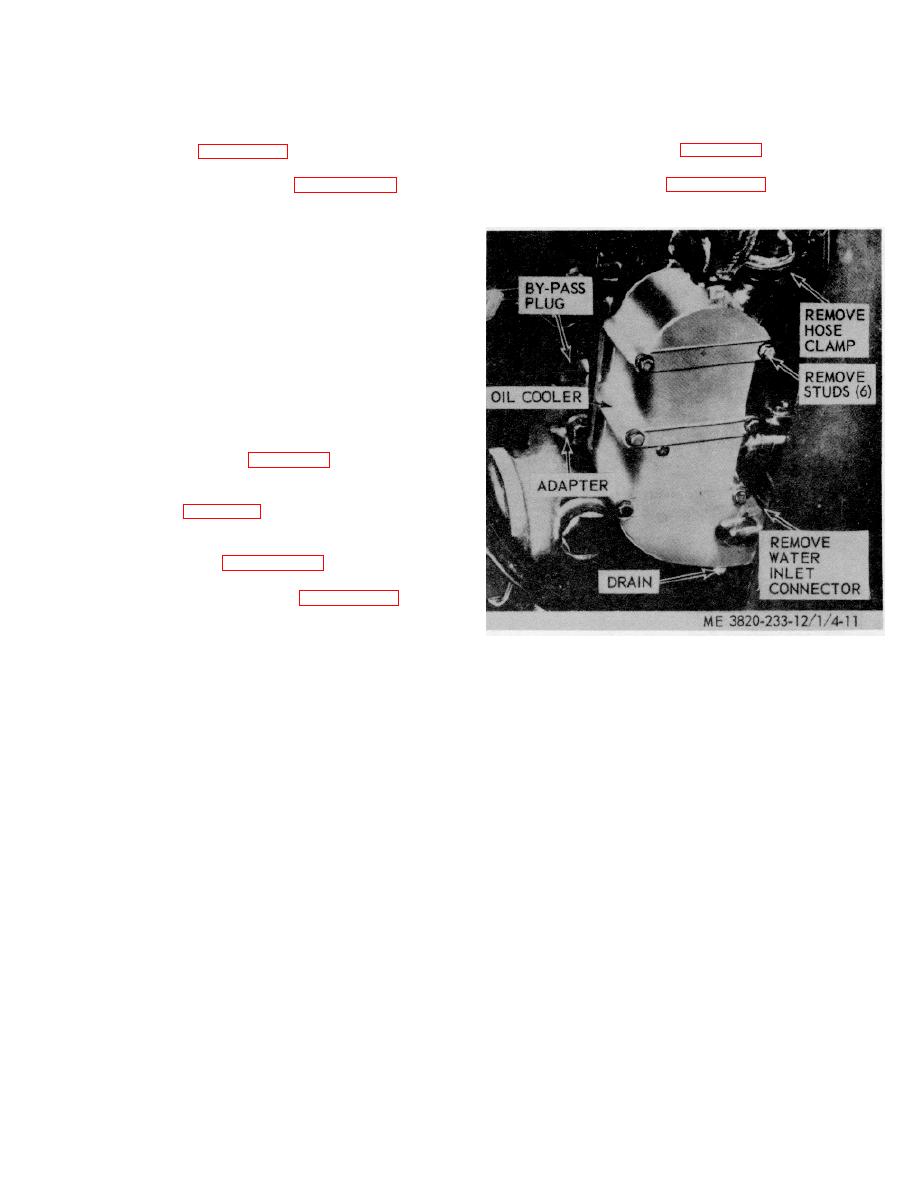

4-21. Oil Cooler

damage.

a. Removal.

(3) Inspect the mounting hardware.

(1) Drain the cooling system.

d. Reassembly. Refer to figure 4-12 and reassemble

(2) Refer to figure 4-11 and remove the oil

the by-pass oil filter.

cooler.

e. Installation. Refer to paragraph 3-8 and install the

b. Disassembly .

Refer to figure 4-10 and

by-pass oil filter element.

disassemble the oil cooler.

c. Inspection. Inspect all parts for cracks, breaks

and damage.

d. Test. The oil cooler core may be checked for

leaks as follows:

(1) Make a suitable plate and attach it to the

flange side of the cooler core. Use a gasket made from

rubber to assure a tight seal. The plate should be drilled

and tapped to permit an air hose fitting to be attached at

the inlet side of the core.

(2) Attach an air hose and apply approximately

75 psi air pressure and submerge the cooler core and

plate assembly in a container of water. Any leaks will be

indicated by air bubbles in the water. If leaks are

indicated, replace the core.

e. Reassembly. Refer to figure 4-10 and reassemble

the oil cooler.

f. Installation.

(1) Refer to figure 4-11 and install the oil cooler.

(2) Fill the cooling system to the proper level.

4-22. By-Pass Oil Filter

a. Removal. Refer to paragraph 3-8 and remove the

by-pass filter element.

b. Disassembly.

Refer to figure 4-12 and

disassemble the by-pass oil filter.

c. Inspection.

(1) Inspect the shell (3) for cracks or damage.

Figure 4-11. Oil cooler, removal and installation.

4-14