TM 5-3820-233-12/2

prime mover air brake system.

2-12. Dolly

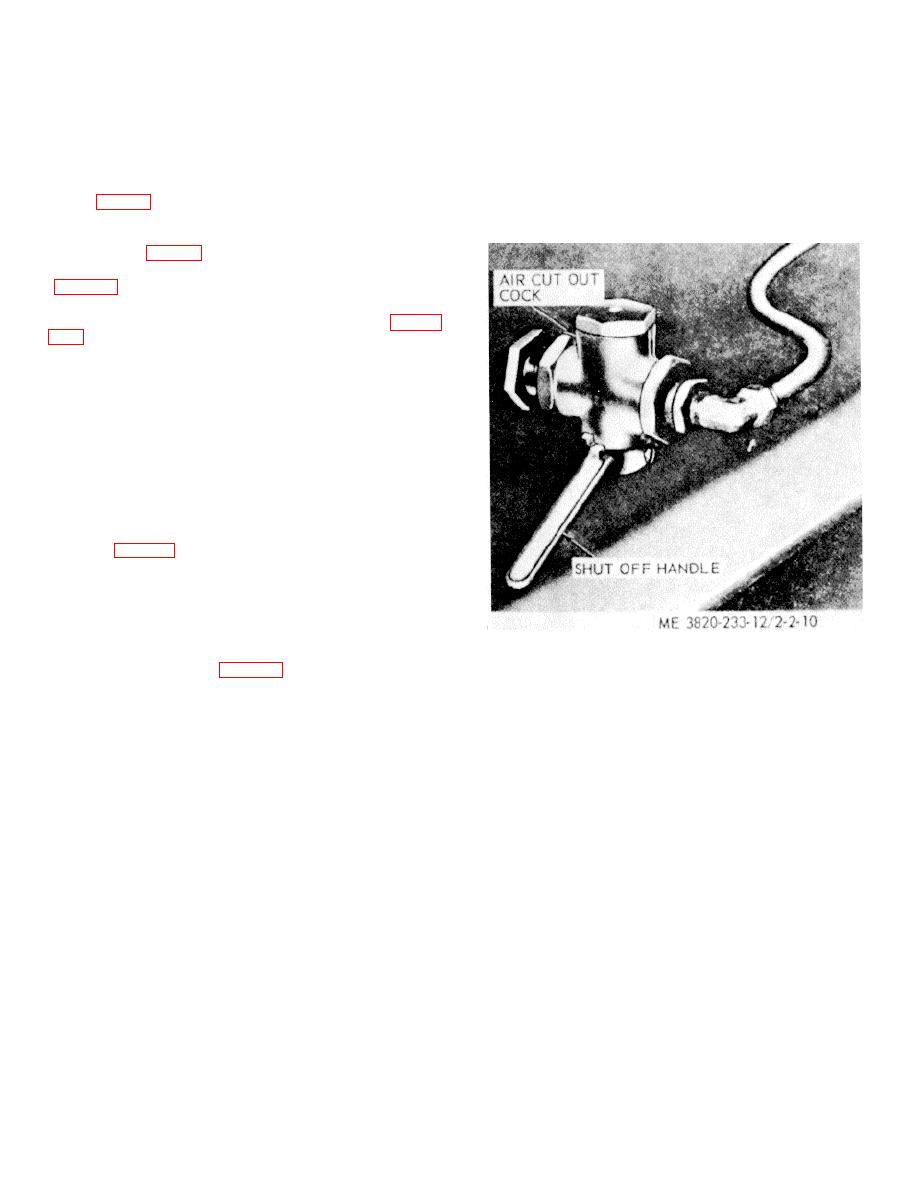

(9) Air reservoir drain cock and cut out cock on

Removal of the dolly is not required for rail transport.

the crushing unit should be in closed position, and cut

The dolly stabilizes the unit for shipment on a flat car.

out cock on prime mover should be open. Prime mover

The dolly is removed however, when the unit is pulled as

brake system is now opera- Live.

a semi-trailer. The dolly is towed behind the unit by use

(10) Test brakes by making a brake application

of a pintle hook, when crusher unit is pulled as a semi-

and observing that crusher brakes apply and release

trailer (fig. 1-1).

properly.

a. Dolly Removal.

(1) Leveling jacks must be left in position for

dolly removal (fig. 2-3B).

(2) Close cut out cock on the dolly air brake line

(3) Remove the dolly air brake feed hose and

install on dummy couplings located on dolly frame (fig. 2-

CAUTION

Failure to cover open hose couplings will

allow sand and grit to enter the air brake

system and settle in the relay valve rendering

the system inoperative.

CAUTION

Chock rear wheels before removing dolly to

prevent moving as dolly is removed and

prime mover attached.

(4) Remove service and emergency air brake

hoses from crusher and attach to dummy couplings on

flexastik (fig. 2-12).

(5) With leveling jacks in place, raise front end of

unit enough to remove weight from dolly.

(6) Release dolly fifth wheel coupler lever, which

releases the fifth wheel from the king pin and pull dolly

away from plant.

(7) Back prime mover into position under crusher

Figure 2-10. Air brake cut out cock.

and couple the two units (fig. 2-13).

(8) Remove dummy coupling and connect to

2-17