TM 5-3820-233-35/2

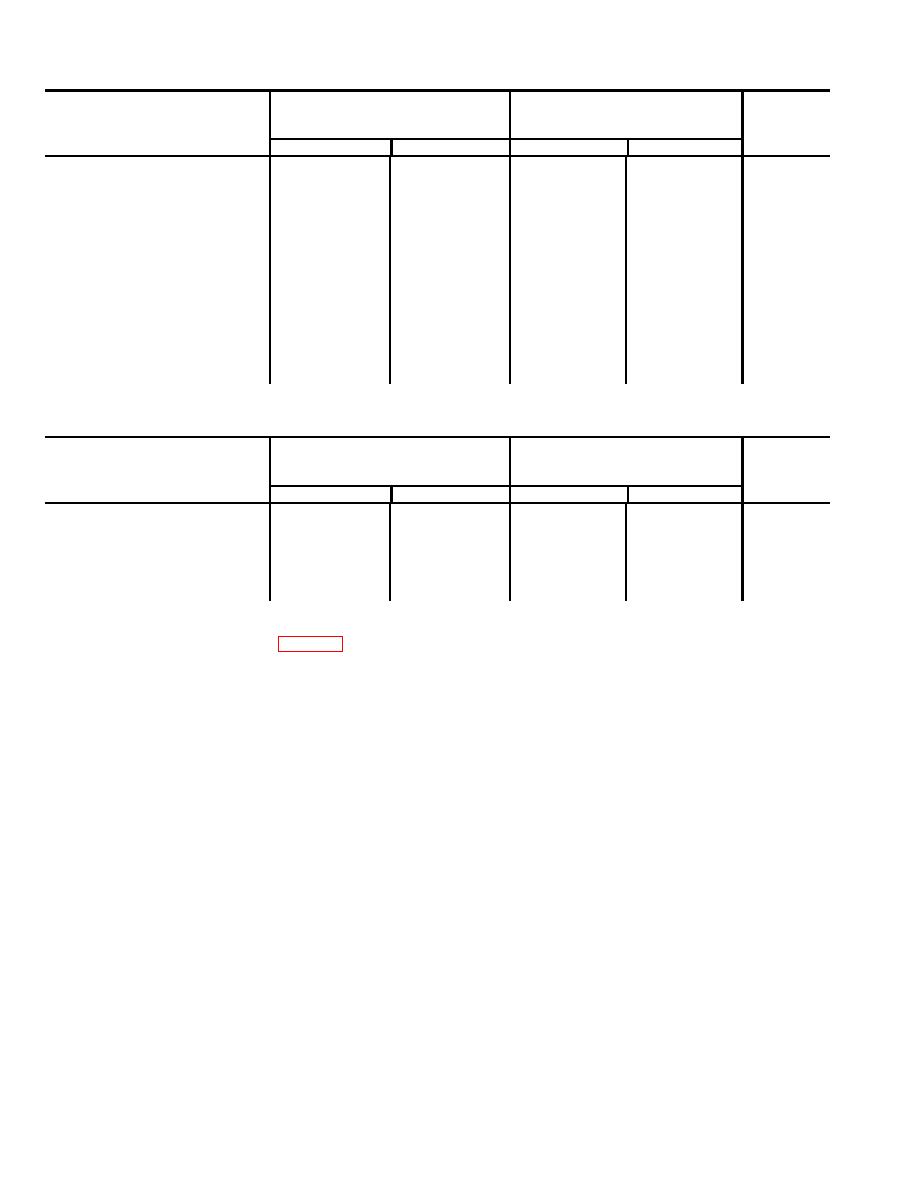

Table 1. Engine Repair and Replacement Standards-Continued.

Manufacturer's

Maximum

dimensions and

Desired

allowable

tolerances in inches

clearance

wear and

Components

Minimum

Maximum

Minimum

Maximum

clearance

Blower:

Backlash-Timing gears

0.0005

0.0025

------

------

0.004

Oil seal (below end plate surface)

0.002

0.008

------

------

------

0.380

------

------

------

------

Pin-dowel (projection beyond inside face of end

plates)

Clearances.

End to end plate--gear end

------

------

0.007

------

------

Rotor to f ad plate-front end

------

------

0.009

------

------

Rotor to housing-inlet side

------

------

0.015

------

------

Rotor to housing-outlet side

------

------

0.004

------

------

------

------

0.002

0.006

0.006

Trailing edge of upper rotor to leading edge

of lower rotor

------

------

------

------

Leading edge of upper rotor to trailing edge

of lower rotor

Table 2. Secondary Crushing and Screening Plant Repair Replacement Standards

Manufacturer's

Maximum

dimensions and

Desired

allowable

tolerances in inches

clearance

wear and

Components

Minimum

Maximum

Minimum

Maximum

clearance

Screen Vibrator Unit

------

------

0.010

------

------

Clearance-inner rotation seal to inner fixed

seal

Roll Crusher

Clearance-spur gear to spur pinion

------

------

0.090

------

------

Backlash-spur gear and pinion

0.016

0.024

------

------

------

m. Schematic Wiring Diagram. Figure 1 shows the schematic wiring diagram for this Portable Secondary Crushing

and Screening Plant.

1-8