3. Install ring gear. Install bolts so internal diameter of

2

Place pinions and thrust washers on differential

ring gear prevents turning of hex head. Install ring

spider, lubricate, and set in position on installed side

gear bolt nuts and torque to 120 to 135 ft. lbs.

gear.

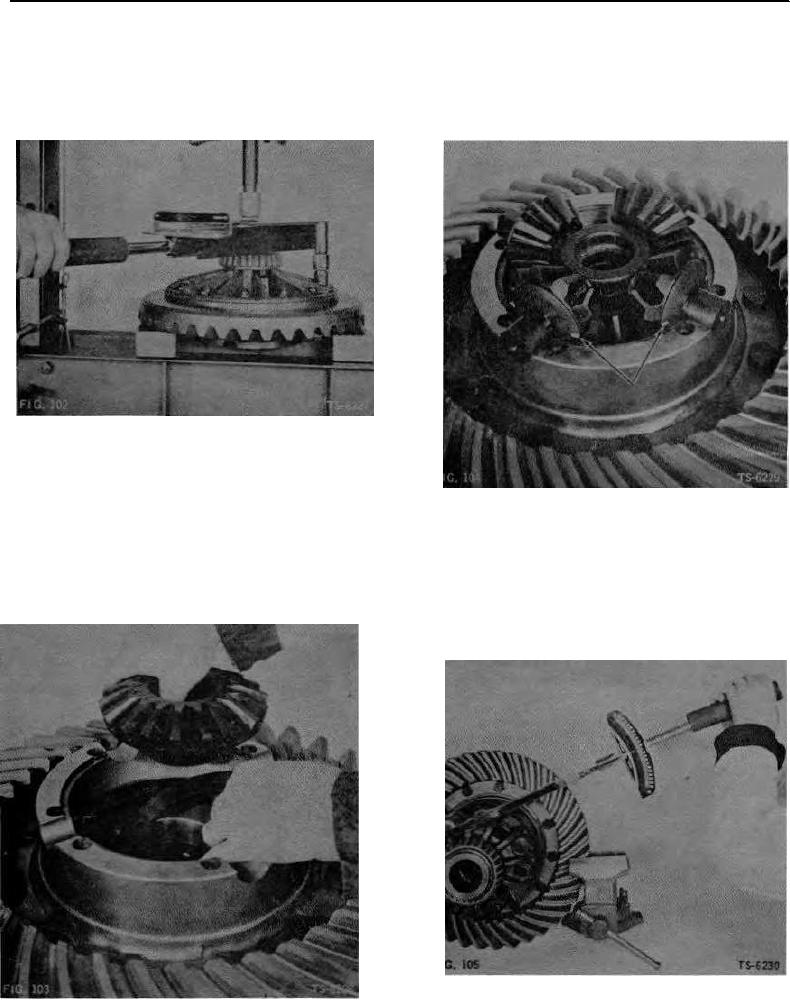

Position ring gear and flanged hub in press and apply

light press pressure to facilitate torquing nuts (Fig.

NOTE: It is very important that tang on each pinion

102).

thrust washer engages groove in case halves as

shown by arrows in Fig. 104.

FIG. 102

NOTE: Axle Part Nos. 130788, 131507, and 190010

are equipped with NoSPIN differentials. Refer to

Figs. 107 through 118 for reassembly instructions.

FIG. 104

Reassembly of Conventional Differential

3. Align match-marks and install remaining case half on

1. Lubricate and install thrust washer and side gear in

other case half assembly, making sure of full gear

differential case and ring gear assembly (Fig. 103).

engagement (Fig. 105). Install bolts and tighten to

Engage holes in thrust washer on dowels projecting

specified torque.

from thrust washer bearing surface in differential

case.

NOTE: Some differential cases are held together with

thru bolts and self-locking nuts instead of bolts in

tapped holes. The bolt heads must extend from the

ring gear side of the case assembly.

FIG. 105

FIG. 103

35