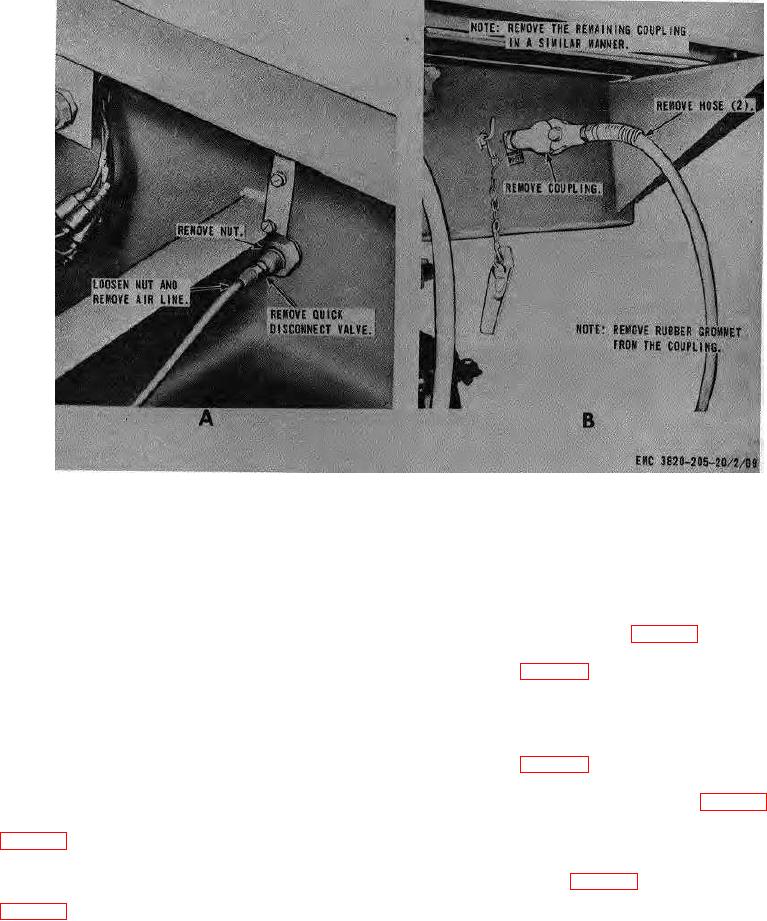

A - Coupling rear view

B - Coupling front view

Figure 74. Coupling, hoses and lines, removal and installation.

Section VII. BELT CONVEYOR ASSEMBLIES

149. General

152. Trough Roller Assembly

The feeder belt conveyor is comprised of the head

a. Removal. Remove the trough roller assembly

section, center section, and tail section and is powered

from the unit as instructed on figure 86.

by an electric motor and gear reducer. The feeder belt

b. Disassembly. Disassemble the trough roller as

conveyor receives the material from the reciprocating

illustrated on figure 87.

feeder and rotary elevator and deposits it on the

c. Cleaning, Inspection, and Repair. Clean and

vibrating screen. The under conveyor belt is powered

inspect all parts. Repair damaged parts. Replace worn

by an electric motor and gear reducer. The under

and defective parts.

conveyor belt receives the crushed material from the

d. Reassembly.

Reassemble the trough roller

crusher rolls and deposits the aggregate in the rotary

illustrated on figure 87.

elevator.

e. Installation. Install the trough roller assembly on

the unit in reverse of the instructions on figure 86.

150. Feeder Conveyor Belt Adjustment

Adjust the feeder conveyor belt as instructed on

153. Feeder Conveyor Return Roller Assembly

a. Removal. Remove the return roller from the

151. Under Conveyor Belt Adjustment

unit as instructed on figure 88.

Adjust the under conveyor belt as instructed on

AGO 8157A

106