1

Key, 5/16 x 5/16 x 2 3/4 in.

18

Screw, No. 12-28 x 3/8 in. (3 rqr)

2

Setscrew, 1/8-32 x 1/4 in.

19

Dust shield

3

Oil slinger

20

Screw, cap, 5/16-18 x 2 in. (2 rqr)

4

Lubrication fitting

21

Washer, special (2 rqr)

5

Pipe plug

22

Screw, cap, 3/8-16 x 3 1/2 in. (4 rqr)

6

Nut, 5/16-18 (2 rqr)

23

Bearing support

7

Screw, cap, 5/16-18 x 2 in. (2 rqr)

24

Screw, No. 12-28 x 3/8 in. (3 rqr)

8

Clamp (2 rqr)

25

Dust shield

9

Fan

26

Rotor

10

Key, woodruff, No. 9

27

Bearing

11

Lubrication fitting

28

Gasket

12

Pipe, special

29

Retainer

13

Pipe, special

30

Bearing

14

Screw, cap, 3/8-16 x 4 in. (4 rqr)

31

Gasket

15

Screw, cap, 5/16 x 2 in. (2 rqr)

32

Retainer

16

Washer, special (2 rqr)

33

Lifting eye

17

Drive end bearing support

34

Frame and field assembly

Figure 36-Continued.

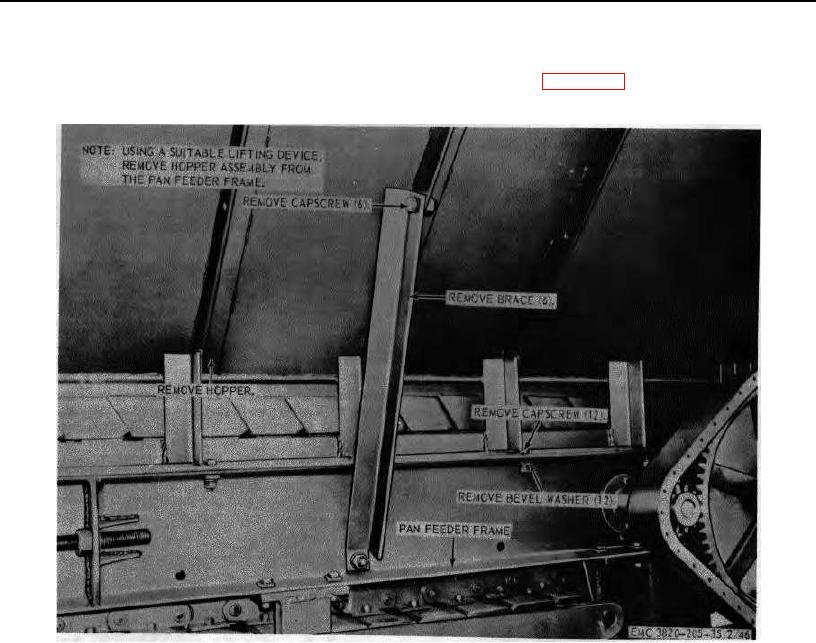

Section II. HOPPER ASSEMBLY

120. General

121. Hopper Assembly Removal

The hopper assembly is a welded construction of

Refer to figure 37 and remove the hopper

plate steel, angle braces, and mounting brackets. It is

assembly from the unit.

the receiving hopper for the rock that is to be crushed.

Figure 37. Hopper assembly, removal and installation.

75 AGO 8456A