TM 5-3820-233-12/2

3-17. Drive Belts

allow oil or grease to accumulate on them. Oil

a. Before Operation Inspection.

not only has a deteriorating effect on rubber,

(1) Wipe all parts of drive unit with a clean cloth.

but also causes slippage and will mix with rock,

(2) Inspect all belts for excessive wear or damage.

thus forming an abrasive compound that will

(3) Inspect wear on conveyor belt fasteners.

prematurely wear the belts and sheave grooves.

CAUTION

b. During Operation Inspection. Inspect all belts for

Do not use belt dressing on V-belts and do not

slippage. If slippage occurs stop unit and tighten belts.

Refer to Table 3-3 for proper V-belt deflection.

Table 3-3. V-Belt Deflection.

Recommended deflection

V-belt location

Defection distance

force in pounds

Minimum Maximum

Engine to main countershaft

1-1/16 inch

11

16

Main countershaft to lower countershaft

3/4 inch

11

16

Lower countershaft to sand conveyor speed reducer

1/2 inch

8

11

Lower countershaft to screen countershaft

1/2 inch

11

16

Screen countershaft to screen vibrating unit

1/4 inch

11

16

Lower countershaft to rock conveyor idler countershaft

7/8 inch

11

16

Rock conveyor idler countershaft to rock conveyor reducer

7/8 inch

8

11

Main countershaft to feed conveyor reducer

1/2 inch

11

16

Main countershaft to roll crusher flywheel

2 inch

11

16

Roll countershaft to elevating wheel countershaft

7/8 inch

11

16

.

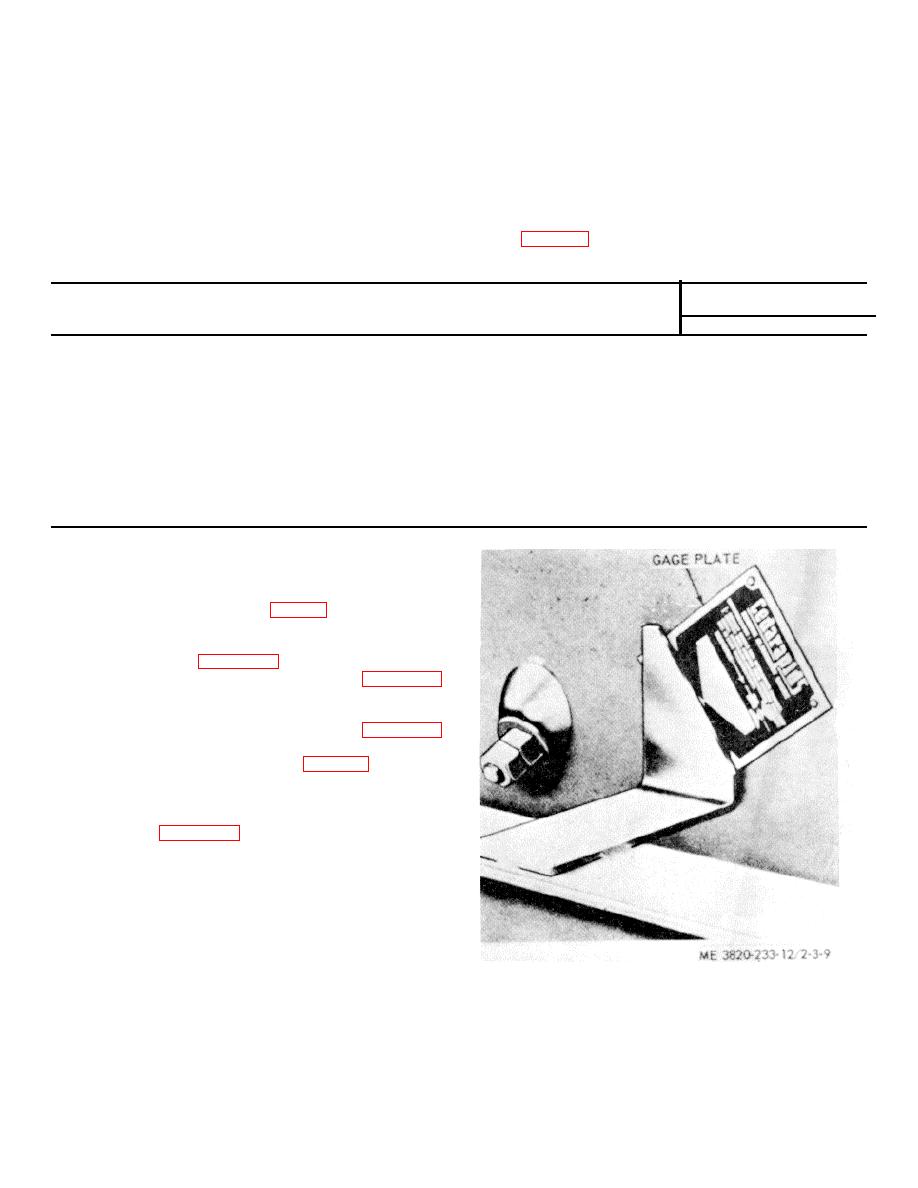

3-18. Screen Alignrnent Gage Plate

The vibrating screen is equipped with a screen alignment

plate. To properly read this plate face the straight edge and

watch the pattern on gage plate (fig. 3-9).

a. If screen is operating correctly a half diamond shape

pattern will be visible and in line with straight edge while

operating as shown in figure 3-10A.

b. If under load, the pattern appears as in figure 3-10B,

the screen box is operating below center. To correct,

compress the coil springs equally, on both sides of box.

c. If above load, the pattern appears as in figure 3-10C,

the screen box is operating above center. To correct,

relieve tension of coil springs equally (fig. 4-68).

d. After the screen has been adjusted properly while

under normal load with equipment stopped, the screen box

will be setting above center when stopped empty as shown

on gage plate in figure 3-10 D.

NOTE

The final check should be made while screen is

operating with load under normal operating

conditions. Screen must be checked daily to

assure screen adjustment at all times.

Figure 3-9. Screen alignment gage plate.

3-15