TM 5-3820-233-12/2

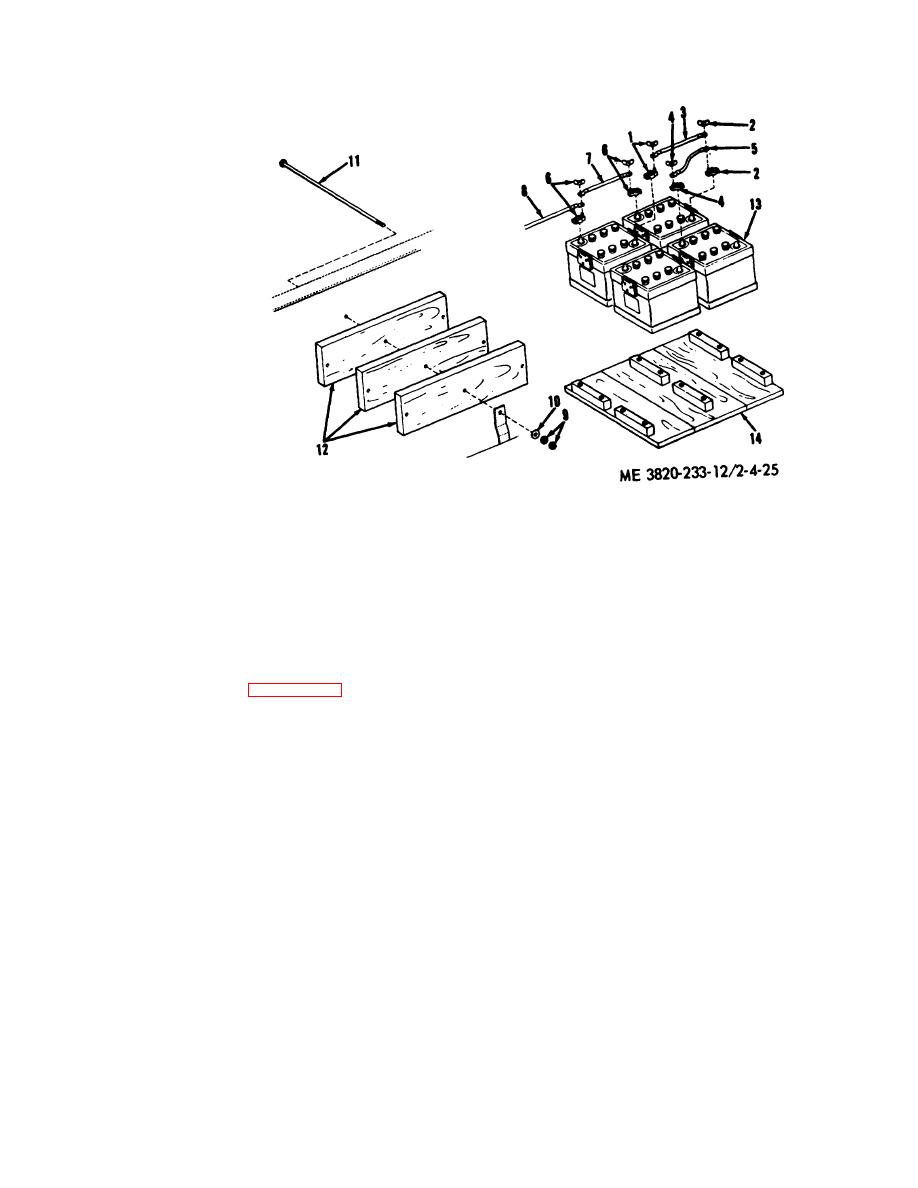

1. Terminal

2. Terminal

3. Cable

4. Terminal

5. Cable

6. Terminal

7. Cable

8. Cable

9. Nut

10. Washer

11. Bolt

12. Clamp

13. Battery

14. Liner

Figure 4-25. Batteries, cables and battery box, removal and installation.

(2) Inspect housing for cracks and inspect gear for

4-41. Starting Motor

cracks or chipped teeth. Replace starter if defective.

a. General. The heavy duty starting motor has a shift

(3) Inspect all wiring for fraying wires or broken

lever and solenoid plunger totally en- closed for protection

connections. Replace if necessary.

from exposure to dirt, icing conditions and splash. It is

(4) Test all control switches, connecting a jumper

located on the lower left side of the engine mounted on the

lead around any switch suspected of being defective. If

flywheel housing.

system functions properly using this method, repair or place

b. Removal. Refer to figure 4-26 and remove the

switch.

starting motor.

(5) Check brushes and replace if required.

c. Inspection.

d. Installation. Install the starter motor in reverse order

(1) Inspect starter motor solenoid for visual defects.

of removal.

Replace if defective.