TM 5-3820-233-12/2

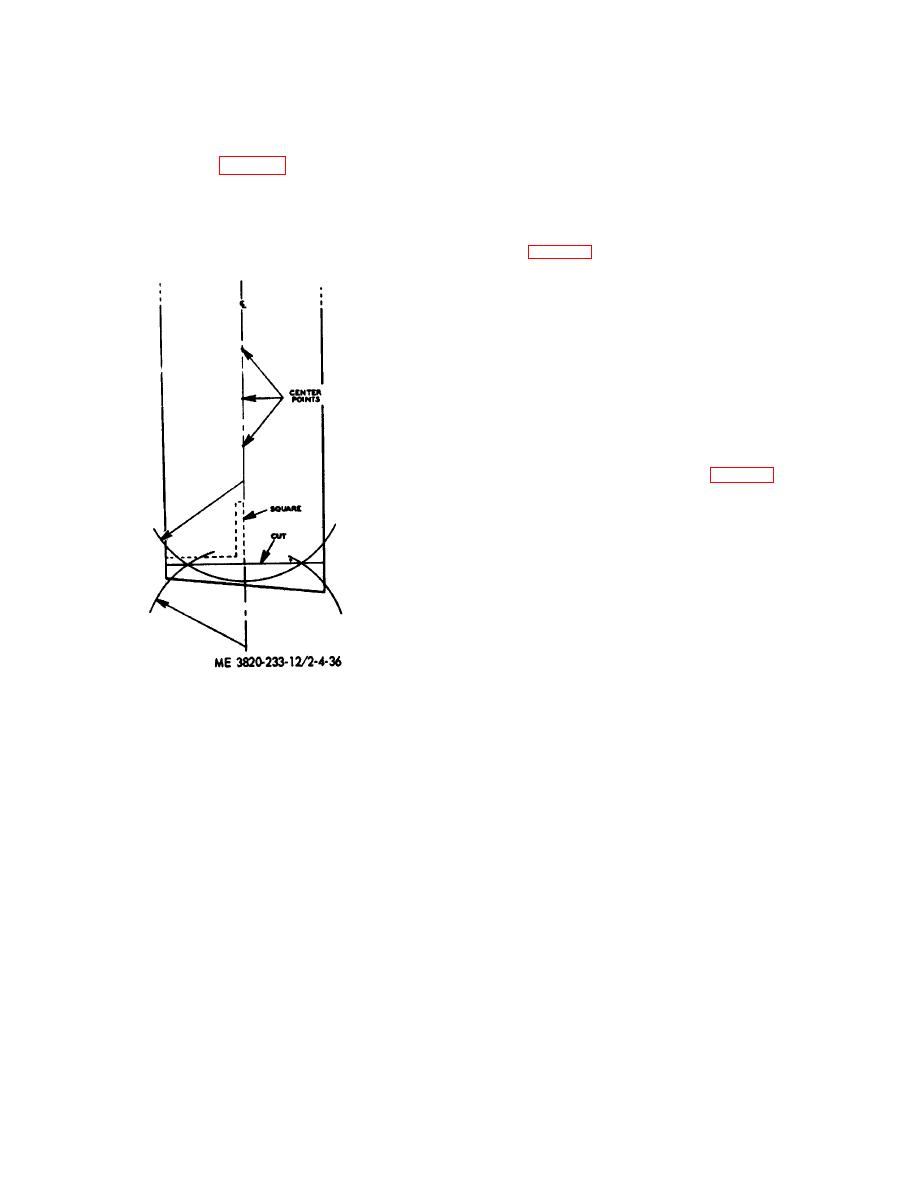

b. Belt Cutting. Molded edges on new belts are not

(4) Assemble stretcher clamp on end of belt

before belt is pulled onto conveyor completely. This will

always straight. It is recommended to square ends of

prevent loose end of belt from traveling up the conveyor

belts with center line of the belt as follows:

and off the head pulley. Attach clamp holding device feet

(1) At intervals of three to five feet mark center

front belt end to permit squaring of belt.

points on belt for 15 feet (fig, 4-36).

(5) Move belt onto the conveyor until squared

(2) Draw an average center line with these points

end is in position where belt will be spliced.

as guides. Pick a point on center line of belt and swing

(6) Install wood belt stretcher clamp on belt 18

an arc through markings to determine cutting for

inches from end of belt, tie assembled clamp to conveyor

squaring belt end.

frame (fig. 4-37).

(3) Using a steel straight edge intersect these

(7) With attached cable pull belt over the top of

two points and cut belt on this line.

squared belt end until correct tension is obtained. Hold

this tension, find center line and mark where belt must

later be cut.

(8) Assemble second belt stretcher clamp 18

inches from belt end and install belt stretcher rods

between clamps tightening nuts until pressure is relieved

from pull cable.

(9) Insert a plank under the belt and cut to

correct length at previously marked line. Using template,

punch holes in both ends of the belt for fasteners.

(10) Wrap belt tape over splice and completely

around belt, then install fasteners (fig. 4-38) as follows:

NOTE

Always use proper size fasteners and correct

belt template to correspond with belt width.

(a) Square belt ends and cut to length.

(b) Support belt with plank and nail template

in position with belt ends tight against lugs.

(c) Punch or bore holes and assemble bolts

in bottom plate. Install belt tape on underside and top

side of belt between belt plate and belt. Insert bolts from

under side along one row of holes.

(d) Place template across end of belt with

bolts in notches and position other end of belt over bolts.

(e) Press belt onto bolts and remove

Figure 4-36. Conveyor belt cutting.

template. Press belt firmly into place.

(f) Place top plate over one bolt and insert

c. Belt Installation. The conveyor belt is cut to

bolt horn assembly tool in other hole to pry second bolt in

approximate correct length at the factory with ample

place. Assemble all top plates in the manner and run

length to permit squaring both ends at assembly.

nuts down by hand.

(1) Uncrate belt and insert bar through center for

(g) Check that plates seat squarely on belt

lifting and threading belt on frame. Check belt to be sure

and tighten nuts.

thickest rubber covering is on the load side.

(h) Hammer plates in belt with metal or hard

(2) Before installing belt be sure adjustable head

wood block as illustrated, and retighten nuts.

pulley is in its shortest position.

(i) Break off bolt ends with bolt breaker. On

(3) Pull belt into position. For convenience in

belts with thick rubber covers, retighten all nuts after a

splicing, ends should come together on top run of

few hours running. Correct application of belt fasteners

conveyor near the tail pulley. If necessary remove

will distribute the strain evenly over the whole plate.

troughing rolls to provide ample room for splicing.

4-32