TM 5-3820-233-12/2

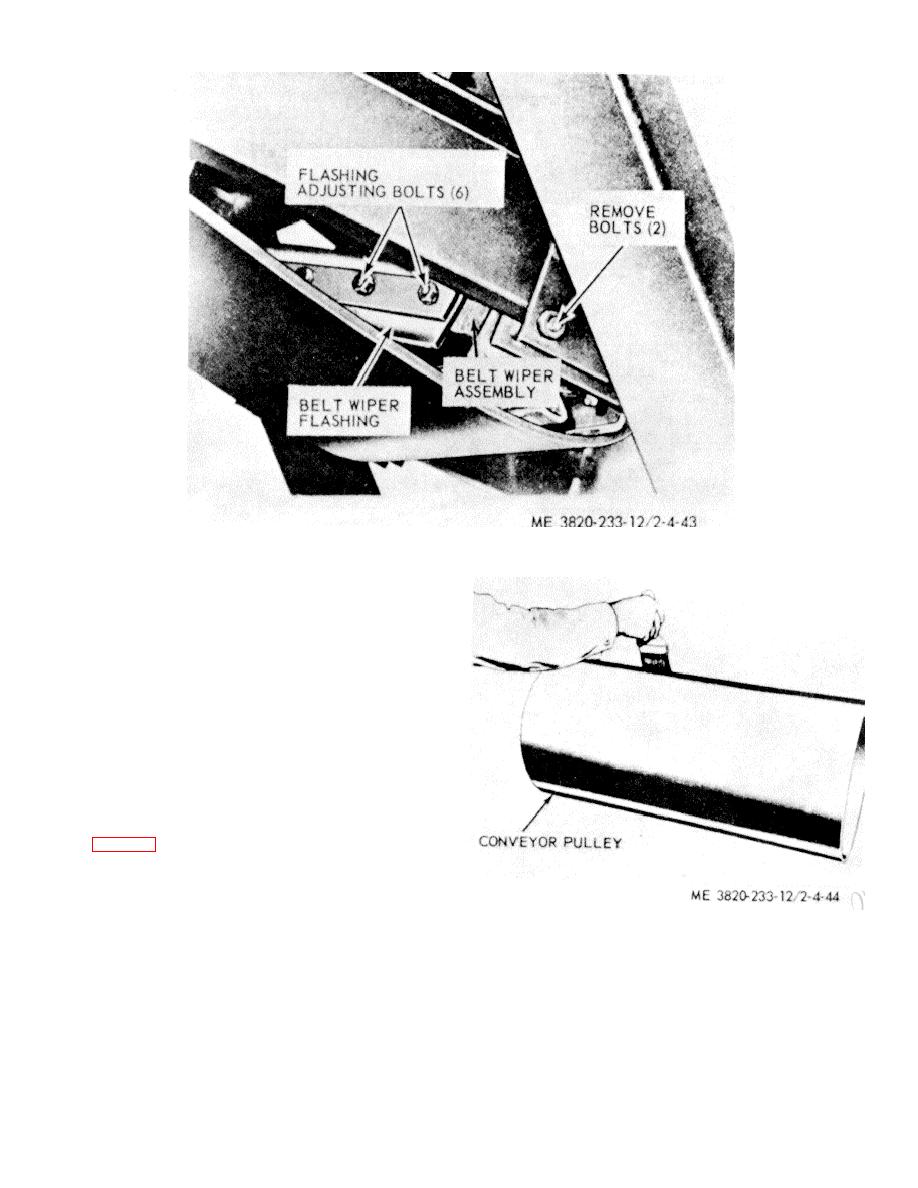

Figure 4-43. Belt wiper, removal and installation.

(2) Move rubber strips down past the metal wiper so

that rubber makes slight contact with belt.

4-54. Conveyor Pulley Lagging

This lagging is optional extra and can be used on all solid

steel head pulleys. Pulley lagging may be applied with

pulley intact on conveyor or with pulley removed, as shown

in illustrations.

a. Remove dust and moisture with an approved

cleaning solvent.

b. Remove all rust spots with coarse steel wool or

sandpaper and brush off any particles of steel weel or

sandpaper dust remaining.

c. Mix adhesive thoroughly and using a 3" brush,

spread adhesive on in a smooth even layer. Cover 1/4 of

area from end to end and allow adhesive to become

tacky.(fig. 4-44).

NOTE

All drive pulleys are lagged with carborundum

coated safety gripped lagging, a kit is available

to apply this lagging in the field. However, it is

necessary to know the pulley diameter and

Figure 4-44. Applying adhesive.

width of face to furnish the correct kit. Kit

consists of: Ribflex lagging 2" W x

necessary length, lagging cement # 14 x Y4"

drive screws. Instruction sheet.

4-37