TM 5-3820-233-35/1

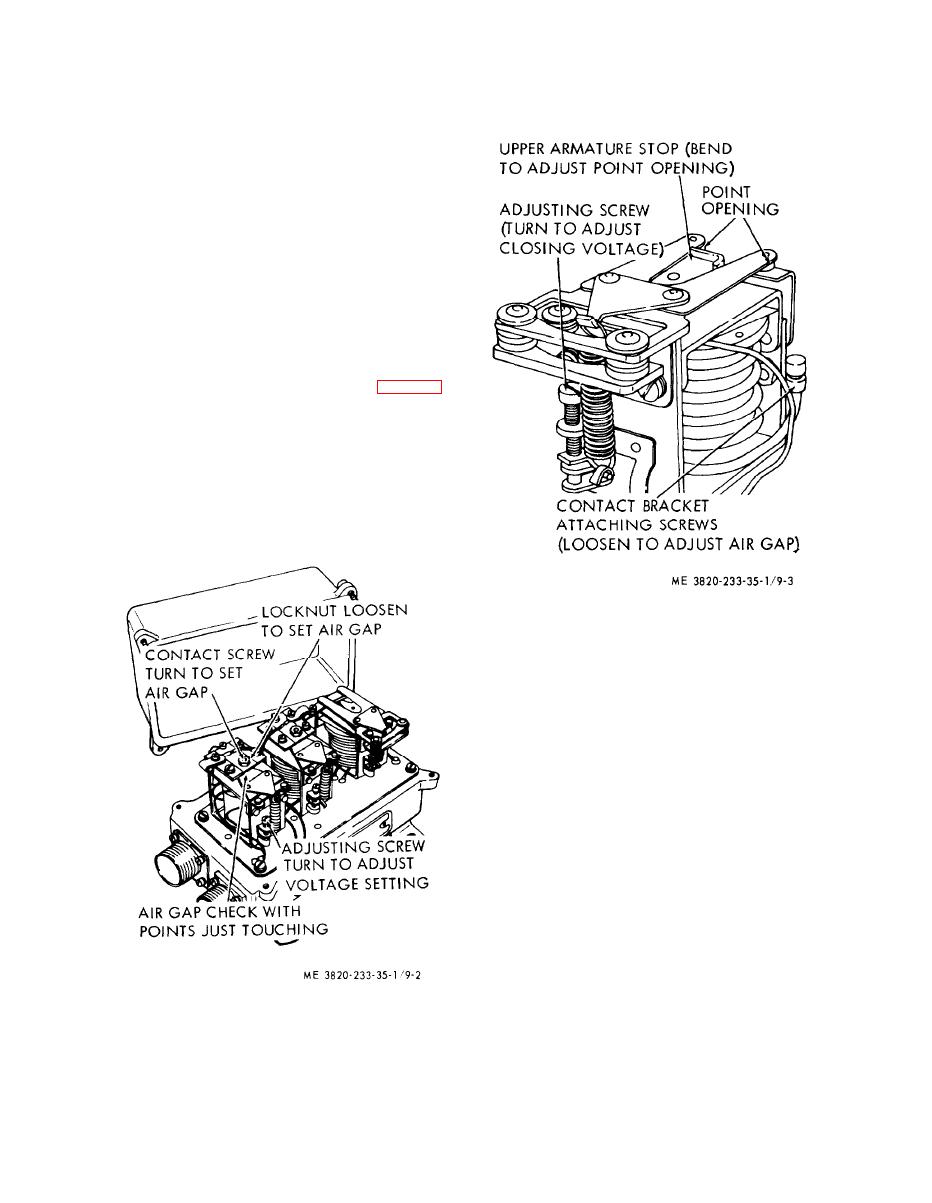

fingers on the armature until points do meet

simultaneously. Adjust air gap by loosening

the two screws attaching the lower contact

bracket, and raise or lower the contact bracket

as required. Be sure the points are properly

lined up and tighten the screws well after ad-

justment.

the

Opening-Measure

(b) Point

point opening and adjust by bending the

upper armature stop.

(c) Closing Voltage-To check the

closing voltage on the cutout relay, insert

Special Testing Harness No. 1 (fig 94) in

between T-l (armature) and the ground

screw at the end of the regulator (fig. 9-5).

Gradually increase generator speed and note

the voltage at which the relay contact points

close. Adjust the closing voltage, if neces-

sary, by turning the adjusting screw at the

base of the cutout relay frame. Increasing the

spiral spring tension increases the relay

Figure 9-3. Cutout relay adjustments.

closing voltage-decreasing the spiral spring

tension lowers the closing voltage.

(2) Voltage Regulator. Two checks and

adjustments are required on the voltage regu-

lator: air gap and voltage setting. Attention

is called to fact that the AIR GAP and not

the POINT OPENING is checked and ad-

justed.

(c) Air Gap-The air gap should be

measured between the armature and the part

of the core (not the residual pin in the core)

next to the residual pin, with the points just

touching. The proper way to measure this air

gap is to push the armature down until the

points open, release until the points barely

close, then measure the air gap. Do not

measure the gap with the flat spring that sup-

ports the contact screw raised up off the fiber

mounting plate. To adjust, loosen the locknut

and turn the contact screw. The most con-

Figure 9-2. Voltage and current regulator adjustments.

3-8