TM 5-3820-233-35/1

(4) Inspect clutch pressure plates for

flatness, cracks, signs of overheating or dam-

age. Replace a defective pressure plate.

(5) Inspect all parts for excessive wear

or damage. Replace defective parts as neces-

sary.

e. Reassembly

(1) Reassemble the power take-off as-

sembly in the reverse of the numerical se-

quence as illustrated on figure 23-2.

(2) After the clutch has been assembled,

keep it engaged until the power take-off is

assembled to the engine.

(3) Refer to paragraph 4 for torque

data.

f. Installation

(1) Refer to figure 23-1 and install the

power take-off assembly.

(2) Install pulley to the drive shaft.

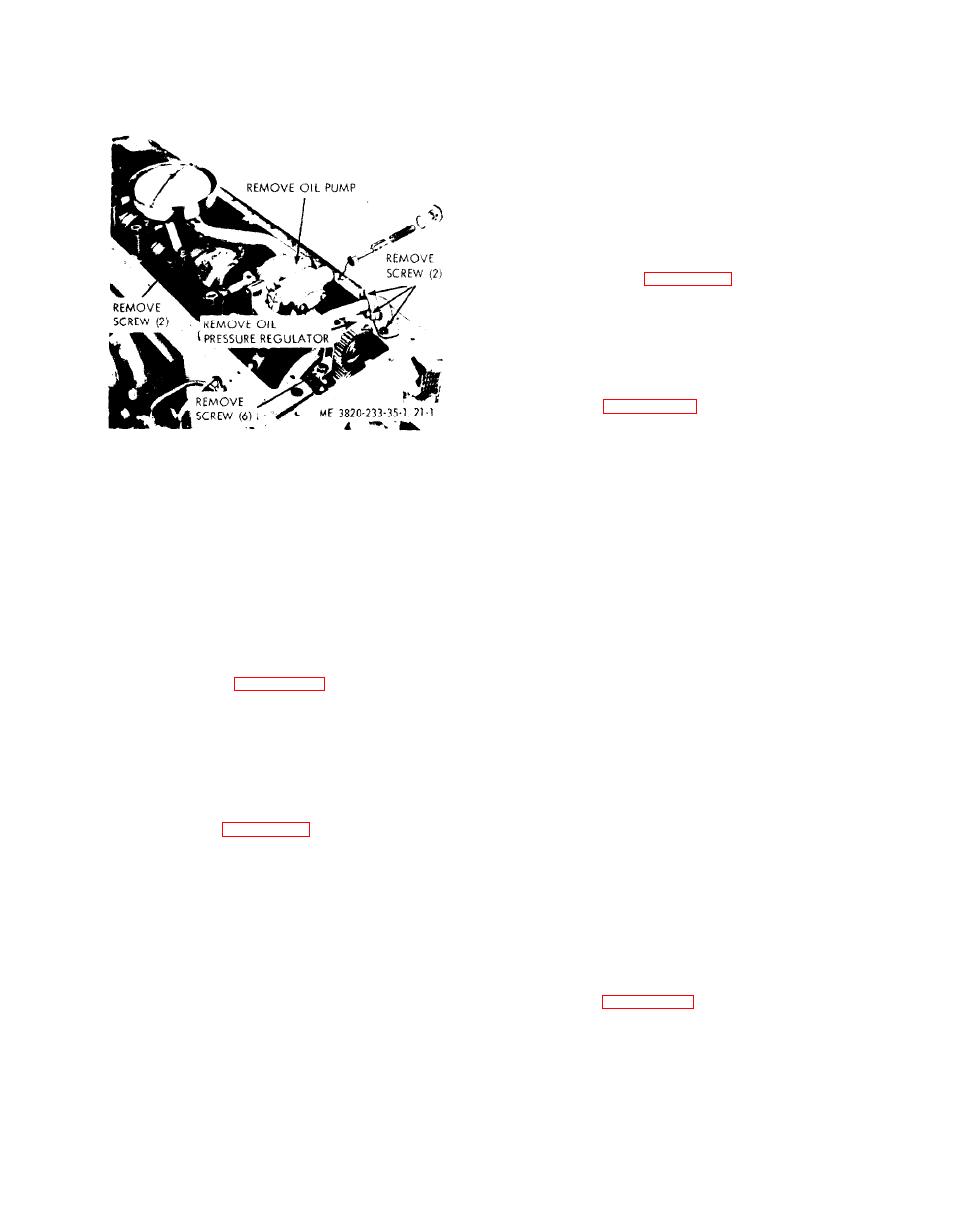

Figure 21-l. Oil pump and pressure regulator assem-

(3) Refer to the Operator's Manual and

bly, removal and installation.

install the hoods, side panels, and tie rods.

(4) Refer to the Operator's Manual and

the plant. The power take-off clutch is a 14

install the air cleaner and muffler.

inch, three piece single plate, dry disc type.

(5) Install the power unit (para 24).

b. Removal

(1) Remove the power unit from the

47. Flywheel and Flywheel Housing

plant (para 24).

(2) Remove the air cleaner and muffler

a. General. The engine flywheel housing is

(Operator's Manual).

mounted on the cylinder block rear end plate

(3) Remove the hoods, side panels, and

and serves as the housing for the flywheel

tie rods (Operator's Manual).

and gear train. The flywheel is bolted and

(1) Remove pulley from the drive shaft.

doweled securely to the end of the crank-

(5) Refer to figure 23-1 and remove the

shaft. A steel ring gear is shrunk fit onto the

power take-off.

rim of the flywheel and is the mating gear

for the starting motor. The flywheel main-

Caution. Do not allow the clutch as-

tains even crankshaft speed and, with the en-

sembly to tip or turn when being removed.

gine starter, provides a method of starting the

This could damage the clutch pilot bearing.

engine.

c. Disassembly. D i s a s s e m b l e t h e p o w e r

b. Removal

take-off assembly in the numerical sequence

(1) Remove the power unit (para 24).

as illustrated on figure 23-2.

(2) Remove the muffler and air cleaner

d. Cleaning, Inspection, and Repair

(Operator's Manual).

(1) Clean all parts with an approved

(3) Remove the hoods, side panels, and

cleaning solvent and dry thoroughly.

tie rods (Operator's Manual).

(2) Inspect the ball and roller bearing

(4) Remove the starter (Operator's Man-

for pitting, corrosion, and rough spots. Re-

ual).

place a defective bearing.

(5) Remove the oil pan (para 43).

(6) Remove the power take-off assembly

(3) Inspect clutch facings for wear, over-

heating, or scoring. Inspect clutch facing

(para 46).

teeth for wear or damage. Replace a defective

(7) Refer to figure 24-1 and remove the

clutch facing.

flywheel.

3-33