TM 5-3820-233-35/1

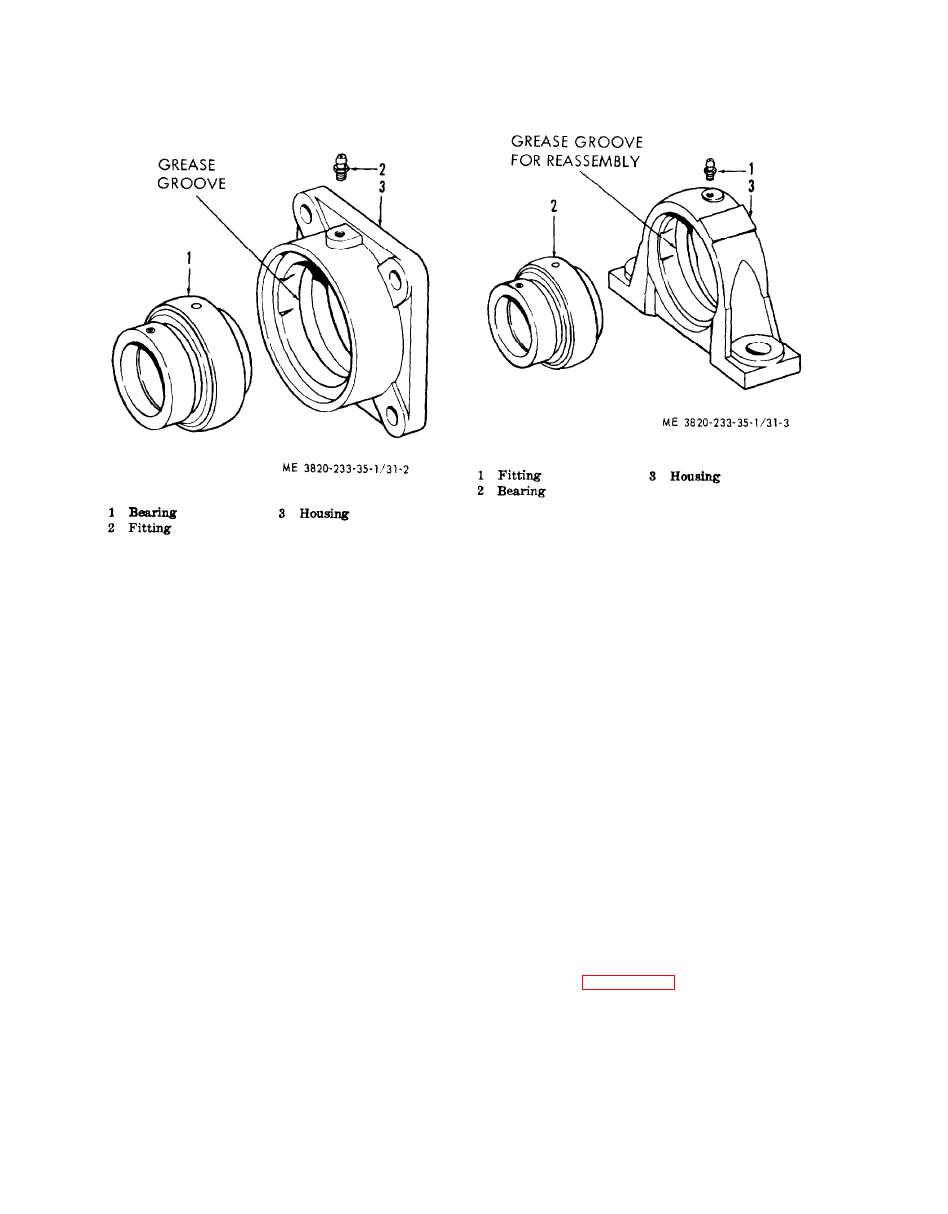

Figure 31-2. Drive crank bearing assembly,

exploded view.

Figure 31-2. Connecting rod beating assembly,

exploded view.

Section III. JAW CRUSHER

58. General

housed roller bearings attached to the crusher

base. The lower end of the pitman is hinged

a. The jaw crusher is used in the primary

on one end of the toggle plate. The other end

plant. It will crush rock down to the size

of the toggle plate oscillates in a groove in

specified in one operation or to a size that

the toggle bearing wedge which is attached

can be further reduced by the roll crusher in

to the crusher base.

the secondary plant.

d. The toggle plate also serves as a safety

b. The jaw crusher consists of two sub-as-

device in the crusher, as it will break when

semblies that can be disassembled for high

uncrushable material passes through the jaws.

level maintenance and overhaul. The base as-

The eccentric crusher shaft and toggle plate

sembly consists of the crusher base, stationary

impart a crushing and downward motion to

jaw, key plates, and adjusting mechanism. The

the pitman and movable jaw as the crusher

shaft and pitman, assembly consists of the ec-

shaft turns. The horizontal length of the

centric shaft, pitman, movable jaw, side and

crushing motion gradually diminishes be-

pitman bearings, side bearing housings, all

tween the top and bottom of the movable

bearing seals and spacers, and two flywheels,

jaw, p r o d u c i n g a l o n g p r i m a r y c r u s h i n g

c. Rock is crushed between the stationary

stroke at the top of the jaw and a short stroke

jaw and the movable jaw. The stationary jaw

for crushing to a more uniform size at the

is held in place in the base by key plates.

bottom. A cross section view of the jaw crush-

The movable jaw is attached to the pitman.

er is shown on figure 32-1.

The pitman is mounted on roller bearings on

the eccentric portion of the crusher shaft, the

e. Jaw crusher size refers to the opening at

concentric ends of which are mounted in

the top of the crusher. This opening is meas-