TM 5-3820-233-35/2

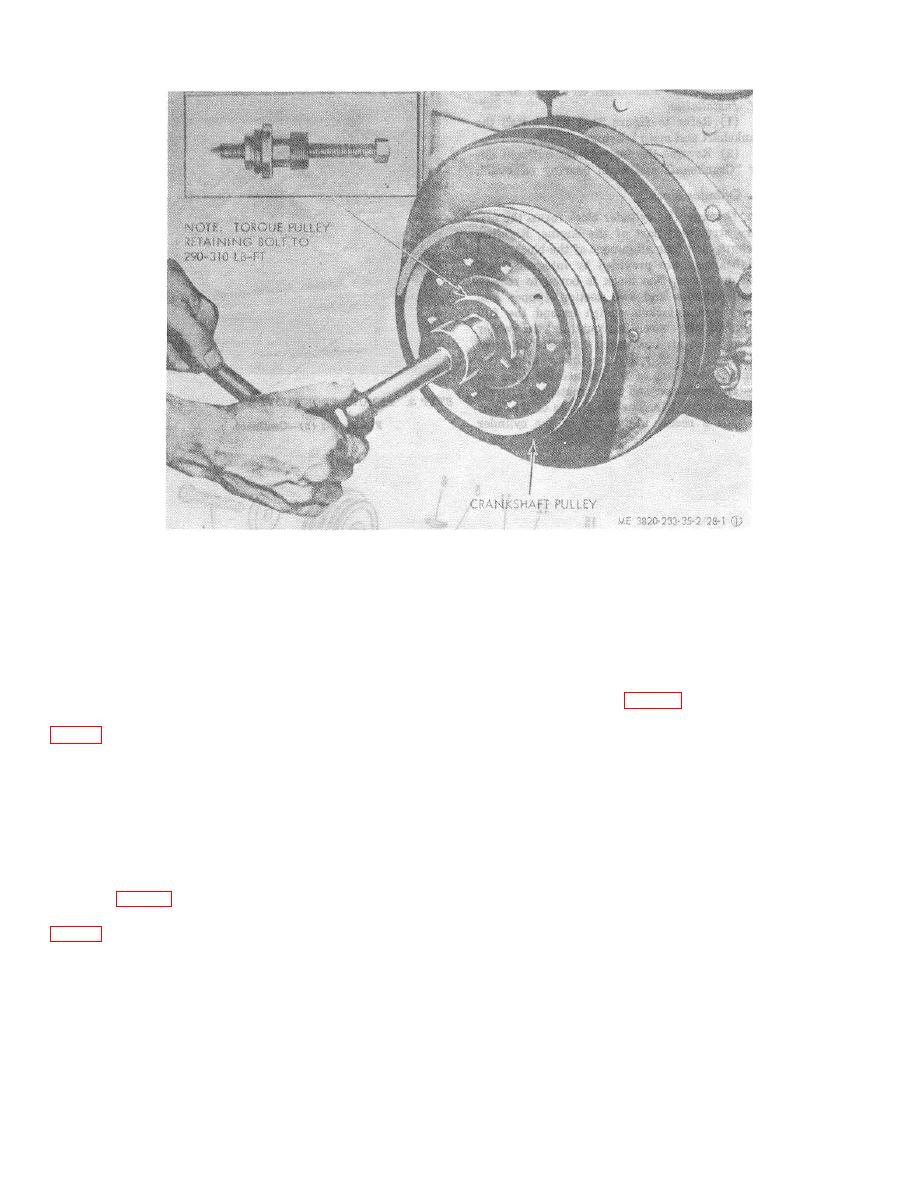

STEP 1. REMOVE CRANKSHAFT PULLEY.

Figure 28-1 (1). Crankshaft pulley and front cover, removal and installation.

(7) Inspect oil pump drive gear and

(2) Perform a magnetic inspection on the

crankshaft timing gear for chipped or cracked teeth.

crankshaft for cracks, breaks, or indications of fatigue.

Replace a defective gear.

Replace the crankshaft if any of the above mentioned

conditions exist.

(8) Measure

journal-to-bearing

shell

tolerance. Refer to table 1 for allowable tolerances.

(3) Measure the main bearing and connecting

Regrind or replace crankshaft as necessary-.

rod journals for wear and out of roundness. Refer to

Caution:

(4) Inspect the thrust washers for wear or

Crankshaft grinding operations must

roughness. Measure washer thickness. Refer to table I

for correct dimensions and tolerance data. Replace

be performed by an adequately

defective washers.

equipped shop and fully trained

personnel.

(5) Inspect main bearings for wear,

roughness., and overheating.

Replace defective

Note.

When a new or reground crankshaft

(6) Check runout of crankshaft journals.

is installed install all new main and

Refer to table 1 for correct tolerance and clearance

connecting rod bearing shells.

data. If the runout limit is greater than the data given in

3-45