TM 5-3820-233-35/2

e. Installation.

(4) Install conveyor drive belts and adjust for

(1) Install speed reducer (fig. 38-1). Tighten

correct belt tension (Operator's Manual).

setscrews on inside collar securely.

(5) Install the main countershaft-to-overhead

(2) Install outside collar and tighten setscrews

conveyor drive guard (Operator's Manual).

securely.

(3) Secure torque arm to support (fig. 38-1).

Section V. ELEVATING WHEEL

64. General

The elevating wheel assembly, rotated by two trunnion

wheels, elevates crushed aggregate received from the

undercrusher conveyor, and discharges it onto the

overhead conveyor for resizing and scalping.

65. Elevating Wheel Assembly

a. Removal.

(1) Remove the elevating wheel assembly

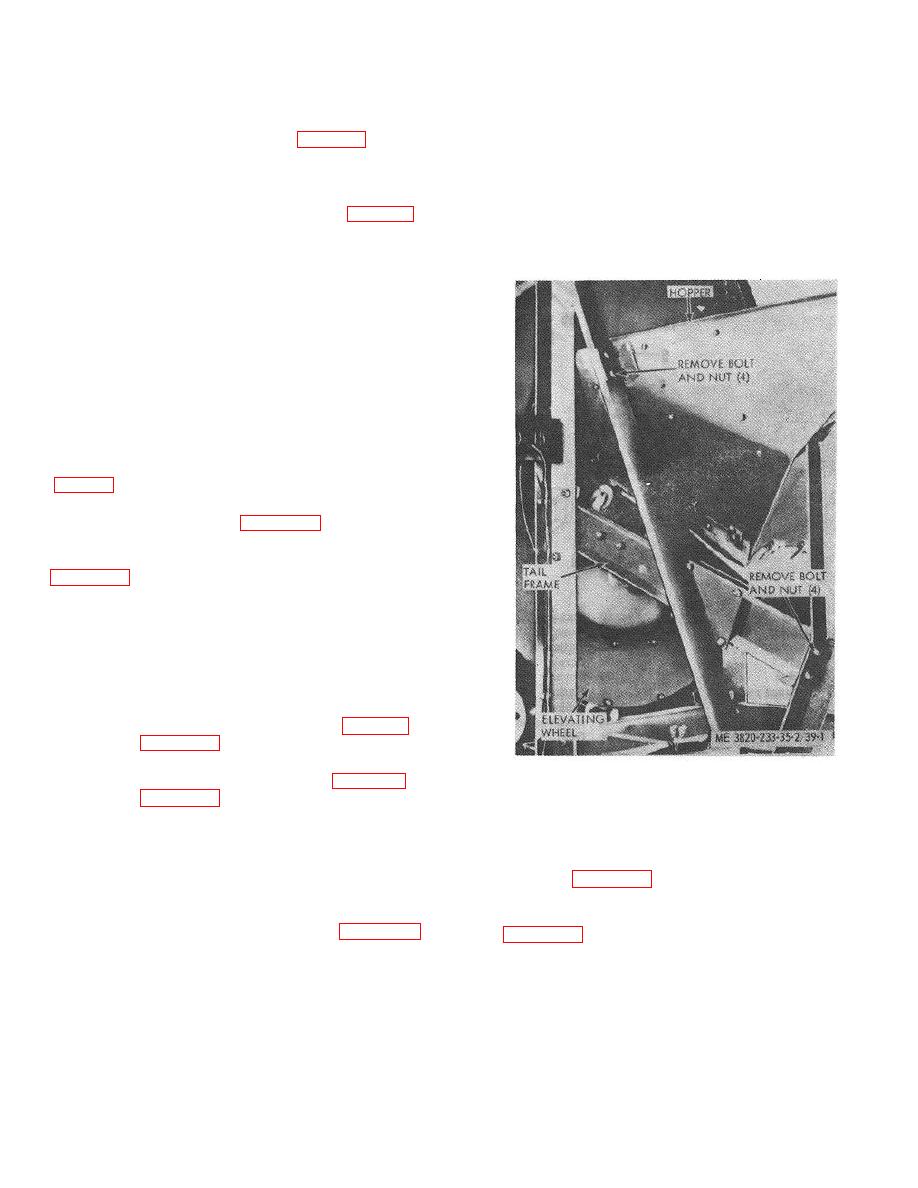

(2) Remove the overhead conveyor tail frame

and hopper as instructed on figure 39-1.

b. Disassembly. Disassemble the elevating wheel

assembly in the numerical sequence as illustrated on

Note

Remove parts 1 through 42 from the

plant, and parts 43 through 134 from

the elevating wheel.

c. Sprocket

Idler

Bearing

Disassembly.

Disassemble the sprocket idler bearing (6, fig. 39-2) as

illustrated on figure 39-3.

d. Trunnion Bearing Disassembly. Disassemble

the trunnion bearing assembly (28, fig. 39-2) as

Figure 39-1. Conveyor tail frame and hopper,

illustrated on figure 39-4.

removal and installation

e. Cleaning, Inspection, and Repair.

(1) Clean all parts in an approved cleaning

g. Sprocket

Idler

Bearing

Reassembly.

solvent and dry thoroughly.

Reassemble the sprocket idler bearing assembly as

(2) Inspect all parts for excessive wear.

illustrated on figure 39-3.

Replace or repair defective parts.

h. Reassembly. Reassemble the elevating wheel

f. Trunnion Bearing Reassembly. Reassemble the

in the reverse of the numerical sequence as illustrated

trunnion bearing assembly as illustrated on figure 39-4.

on figure 39-2.

4-20