TM 5-3820-233-35/2

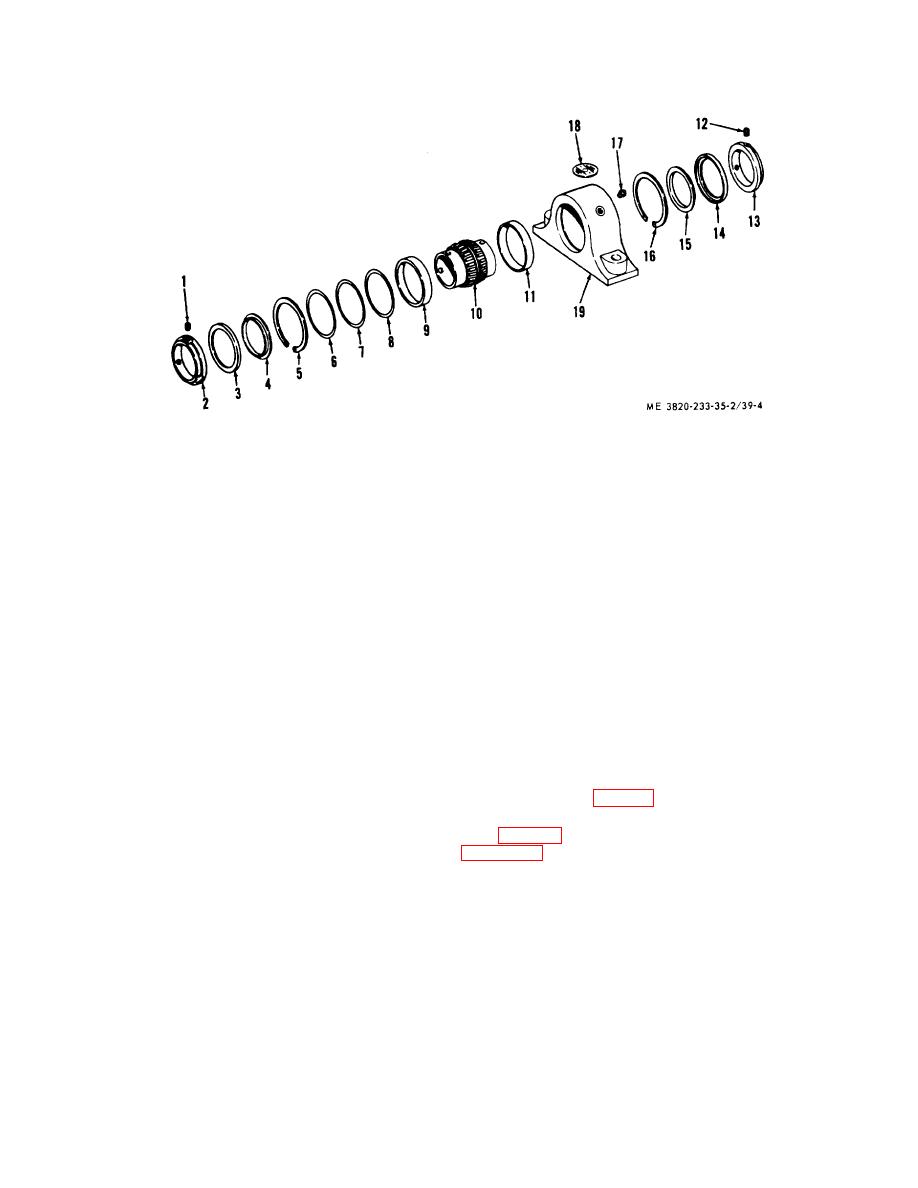

1

Setscrew

8

Shim

15

Seal

2

Collar

9

Bearing cup

16

Snap ring

3

Seal

10

Bearing cone

17

Fitting

4

Seal

11

Bearing cup

18

Identification plate

5

Snap ring

12

Setscrew

19

Housing

6

Shim

13

Collar

7

Shim

14

Seal

Figure 39-4. Trunnion bearing assembly.

Section VI. VIBRATING SCREEN AND VIBRATOR UNIT

forward toward the discharge end of the screen providing

66. General

efficient screening action and separation of the aggregate

The vibrating screen receives aggregate from the

according to size screen wire openings in the box. The

overhead conveyor. It is composed of three major

oversized aggregate drops from the discharge end of the

subassemblies: a welded steel base, full floating screen

vibrating screen to the roll crusher for resizing.

box, and a screen vibrator unit. The screen vibrator

unit, from which the screen derives its motion, is driven

67. Vibrating Screen

by V-belts from the screen drive countershaft. The

directional movement of the screen box is determined

a. Removal

by the position of the two eccentric shafts of the

(1) Remove the vibrating screen, vibrator unit,

vibrating unit, and the angular position of the screen box

and screen hopper (para 27).

support springs. During each cycle of the screen action,

(2) Place a suitable support under the vibrator

the screen box and aggregate move forward and upward

unit (fig. 40-1) and remove capscrews and nuts (38 and 40,

at an angle of 35

.

When the extreme upward

movement is reached, the screen drops away from the

aggregate. Each cycle lifts the aggregate and moves it

4-25