TM 5-3820-205-10-1

CHAPTER 3

MAINTENANCE INSTRUCTIONS

Section I. OPERATOR'S TOOLS AND EQUIPMENT

26.

Special Tools and Equipment

There are no special tools or equipment required to perform operator maintenance on the roll crusher.

27.

Basic Issue Item Tools and Equipment

The basic issue item tools and equipment authorized for or initially supplied with the roll crusher are listed in

Appendix II.

Section II. LUBRICATION

28.

General Lubrication Information

a.

This section contains general lubrication instructions and supplemental lubrication instructions

which are not specifically covered in the lubrication order.

b.

Refer to LO 5-3820-205-12-1 for specific lubrication instructions.

29.

Detailed Lubrication Information

a.

Care of Lubricants. When storing or handling lubricants, ensure that the containers are clean

and securely covered to prevent dirt, dust, or other foreign matter from entering. Ensure that the lubricant is

clean before using it.

b.

Cleaning. Clean all surfaces surrounding the point to be lubricated before applying the

lubricant. Use a clean cloth dampened in an approved cleaning solvent to clean the surface before lubricating.

Remove all excess lubricant after lubrication.

c.

Points of Application. The points of application can be located by referring to LO 5-3820-205-

12-.

Caution: Over-lubrication may cause equipment failure or damage to working parts.

d.

Special Lubrication Instructions for Unusual Conditions. Lubrication intervals will be more

frequent when operating the roll crusher during extremely high or low temperature, in dust or sand, or under any

condition which tends to destroy the protective quality or quantity of the lubricant.

e.

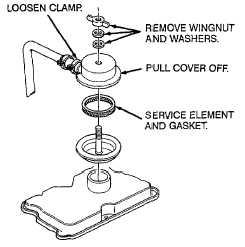

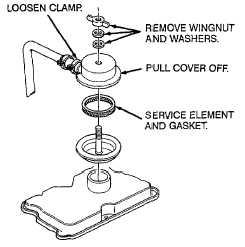

Crankcase Breather. Service the crankcase breather (fig. 37).

f.

Engine Oil. When using OEA oil in the crankcase, observe the following precautions:

(1) The crankcase oil level must be checked frequently as oil consumption may increase.

(2) The oil may require changing more frequently than usual because contamination by dilution

and sludge formation will increase under cold weather operating conditions

TA507900

Figure 37. Crankcase breather service.

31