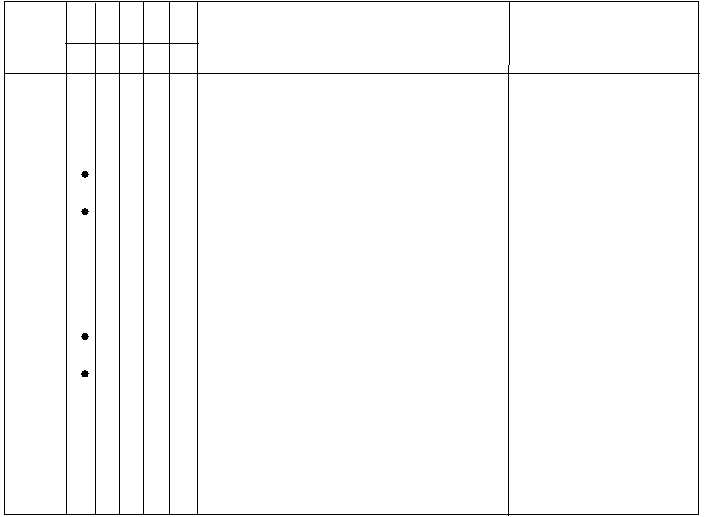

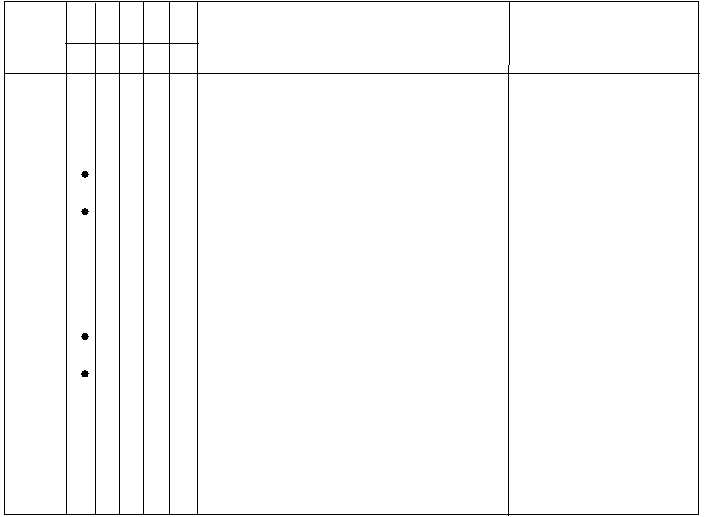

INTERVAL

TM 5-3820-205-10-1

LEAKAGE DEFINITIONS FOR Operator/Crew PCMS

Class I

Seepage of fluid (as indicated by wetness or discoloration) not enough to form drops.

Class II

Leakage of fluid great enough to form drops, but not enough to cause drops to drip from item

being checked/inspected.

Class III

Leakage of fluid great enough to form drops that fall from the item being checked/inspected.

Caution: Equipment operation is allowable with minor leakages (Class I or II). Consideration must

be given to the fluid capacity in the item/system being checked/inspected. When in doubt, notify your

supervisor.

When operating with Class I or II leaks, continue to check fluid levels as required in your PMCS.

Class III leaks should be reported to your supervisor or to organizational maintenance for corrective

action.

32. Operator/Crew Preventive Maintenance Checks and Services (PMCS)

B BEFORE

D DURING

A AFTER

W WEEKLY

M MONTHLY

B

D

A

W

M

Note: Perform Weekly (W) as well as Before (B) operation if:

1. You are the assigned operator and have not operated

the roll crusher since the last weekly.

2. You are operating the roll crusher for the first time.

1

EXTERIOR OF EQUIPMENT

a.

Visually check for fluid leakage or appearance

Class III Leaks.

of fluid leakage.

b.

Visually check for damaged piping or hoses.

Broken piping or hoses.

2

OPERATOR'S ELECTRICAL CONTROL PANEL

Warning: Do not connect electrical power or operate

the equipment if the ground connection is not properly

installed (fig. 8). Death by electrocution could result

from improperly grounded equipment.

·

a.

Visually check to see if ground rod is securely

Roll crusher not grounded.

mounted and there are no loose connections.

·

b.

Check for proper operation. Ensure that switches are

in the correct positions and cables are connected

(fig. 35).

33

ITEM

NO.

ITEM TO BE INSPECTED

PROCEDURE: CHECK FOR AND HAVE REPAIRED,

FILLED, OR ADJUSTED AS NEEDED

EQUIPMENT IS NOT

READY/AVAILABLE IF: