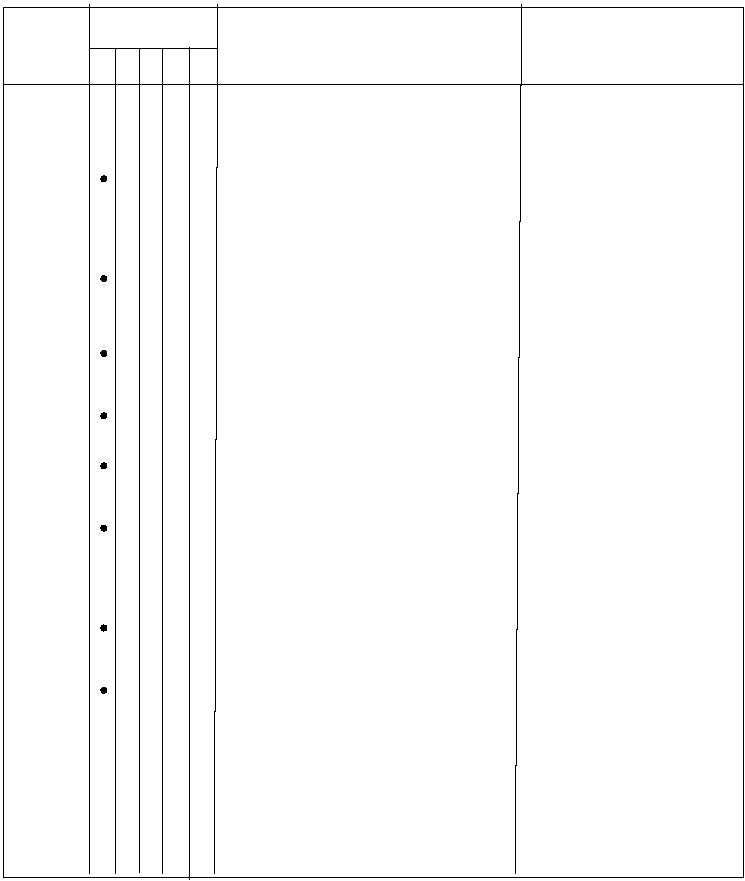

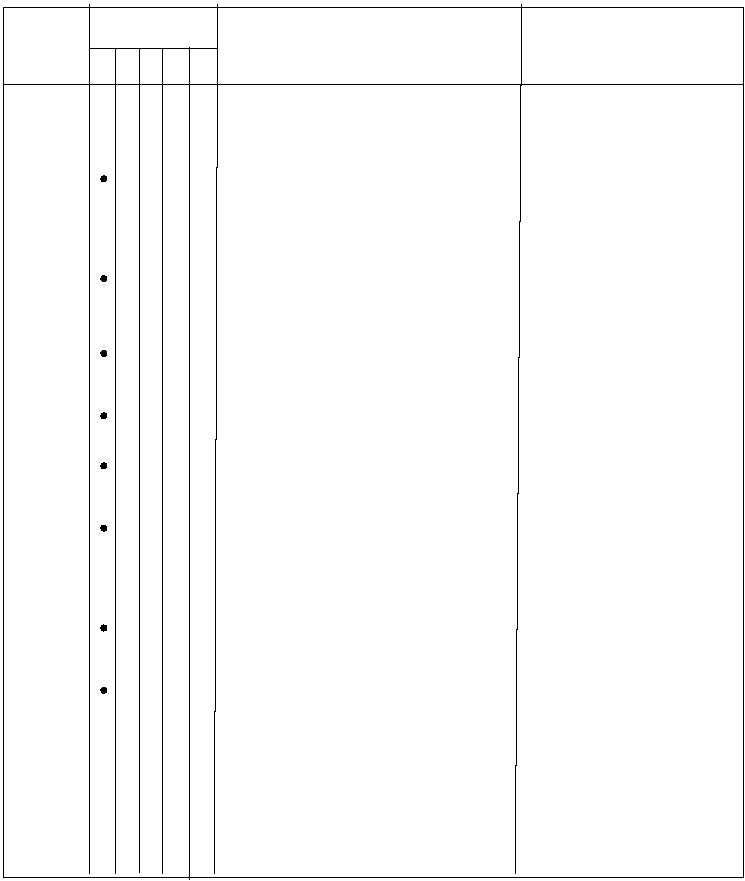

INTERVAL

TM 5-3820-205-10-1

B BEFORE

D DURING

A AFTER

W WEEKLY

M MONTHLY

B

D

A

W

M

3

MAIN ELECTRICAL CONTROL PANEL

Warning: Do not connect electrical power or operate

the equipment if the ground connection is not

properly installed (fig. 8). Death by electrocution

could result from improperly grounded equipment.

Move main power switch to OFF position, and ensure

Circuit breakers off. Loose

that all circuit breakers are in the ON position.

or disconnected cables.

Check for loose or disconnected capes. Return

main power switch to ON position.

4

CONVEYOR BELT AND ASSEMBLIES

·

Check conveyor belt for excessive wear, frayed, or

Broken conveyor belt or roller

cut condition. Check for broken roller assemblies.

assemblies. Loose fastener.

Inspect belt fastener assembly.

5

DRIVE BELTS

Visually check for broken or missing drive belts or

Drive belts missing or broken

glazed, shiny surface which indicates drive belt slippage.

.

6

VIBRATING SCREEN

Check rubber mountings for tears and cracks.

Rubber mountings torn through

or cracked.

7

RECIPROCATING FEEDER

·

Check for cracks, breaks, and freedom of movement.

Cracks or breaks in feeder

assembly

8

ROLL CRUSHER ASSEMBLY

·

Check for cracks, breaks, and leftover aggregate.

Roll crusher assembly cracked,

Check tension spring for proper adjustment

twisted, or rock lodged in roller.

(para 68). Check gearbox oil before operation and

after every ten hours of operation (LO 5-3820

.

205-20-1).

9

FIRE EXTINGUISHER

·

Inspect for full charge by checking gage and check-

Gage not reading in green, or

ing for broken seal.

seal broken

.

10

ENGINE CRANKCASE

·

With roll crusher in a level position, check engine oil

Oil level at or below "L” mark.

level and maintain oil level between "L” (low) and

"H" (high) marks.

34

ITEM

NO.

ITEM TO BE INSPECTED

PROCEDURE: CHECK FOR AND HAVE REPAIRED,

FILLED, OR ADJUSTED AS NEEDED

EQUIPMENT IS NOT

READY/AVAILABLE IF: