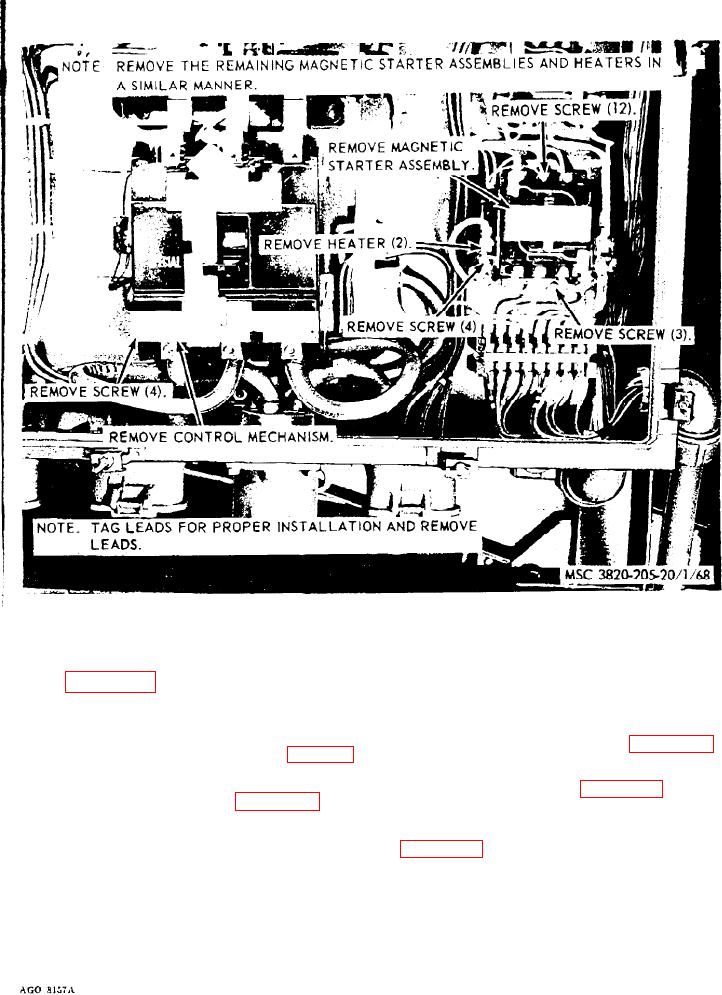

Figure 68. Control mechanism, magnetic starter, and heater, removal and installation.

or missing hardware, corrosion, and frayed

f. Installation. Install the tail and blackout

or damaged insulation. Repair or replace a

lights (par. 107).

damaged part as necessary.

139. Clearance Marker lights

d. Lamp and Lens Replacement. Replace the

a. Removal. Remove the clearance marker

lamps and lenses as illustrated on figure 76.

lights from the unit as instructed on figure 75.

e. Reassembly. Reassemble the clearance

b. Disassembly. Disassemble the clearance

marker lights illustrated on figure 76.

marker lights as illustrated on figure 76.

f. Installation. Install the clearance marker

lights on the unit in reverse of the instructions

c. Cleaning, Inspection, and Repair. Clean

and inspect all parts for breaks, cracks, loose

on figure 75.

Section VI. RECIPROCATING FEEDER ASSEMBLY

assembly consists of a feeder grizzly, upper

140. General

hopper, feeder hopper, and reciprocating feeder

The reciprocating feeder assembly controls

plate. The feeder plate moves back and forth

the flow of material to the roll crusher. The

99