b. Cleaning, Inspection, and Repair. Clean and

c. Installation. Install the crusher chute and liner

inspect all parts. Replace or repair all defective or

on the unit in reverse of the instructions on figure 99.

damaged parts.

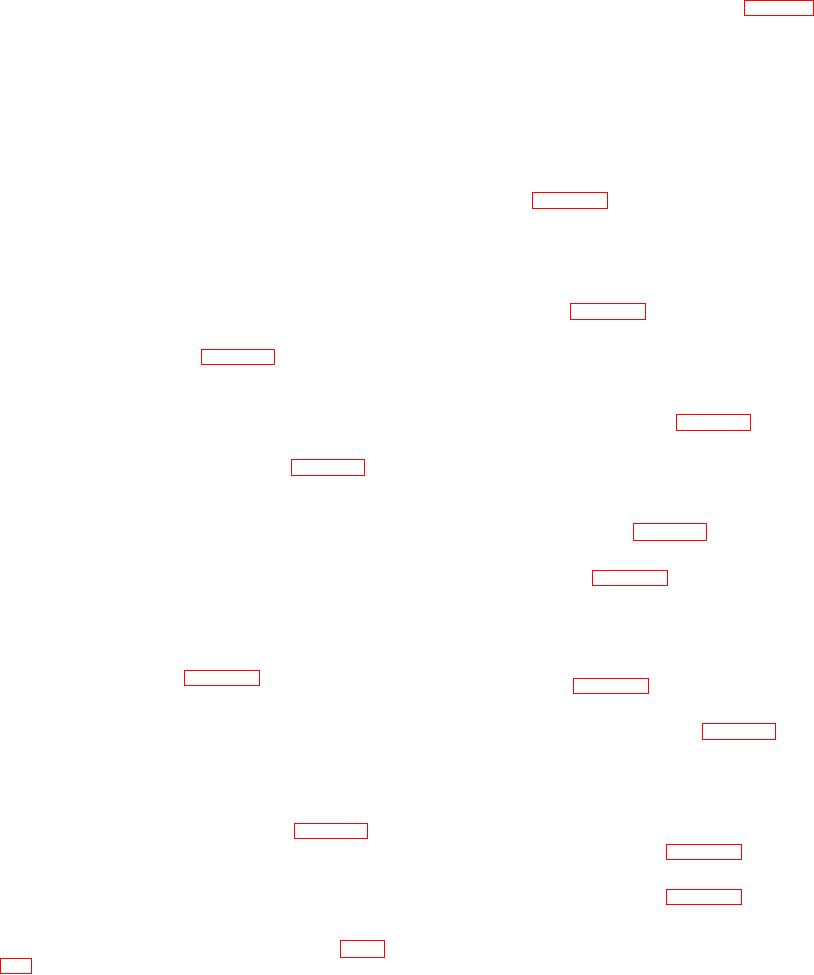

Section X. VIBRATOR SCREEN ASSEMBLY

164. General

b. Cleaning and Inspection. Clean and inspect all

parts. Replace a defective or damaged part.

The screen vibration is produced by the

c. Installation.

Install the discharge chute

eccentric shaft and balance wheels. The shaft is driven

extension and liners on the unit in reverse of the

by a 15-horsepower electric motor. The capacity of

instructions on figure 102.

screening depends upon the slope, throw, and

revolutions per minute of the mechanism, screen

surface used, and whether the mechanism is operated

168. Discharge Gate

for the flow or counterflow of aggregate on the screens.

165. Balance Wheel Assembly

a. Removal. Remove the discharge gate from the

unit as instructed on figure 103.

a. Removal. Remove the balance wheel assembly

b. Cleaning, Inspection, and Repair. Clean and

from the unit as instructed on figure 100.

inspect all parts. Repair or replace a damaged part as

necessary.

b. Cleaning and Inspection. Clean and inspect the

balance wheel assembly.

Replace a defective or

c. Installation. Install the discharge gate on the

damaged balance wheel assembly.

unit in reverse of the instructions on figure 103.

c. Installation. Install the balance wheel assembly

on the unit in reverse of the instructions on figure 100.

169. Lower Screen Hopper

166. Vibrator Screen Support Bar and Rubber

a. Removal. Remove the lower screen hopper

Deflectors

from the unit as instructed on figure 104.

b. Disassembly. Disassemble the lower screen

a. Removal.

hopper as illustrated on figure 105.

(1) Remove the vibrator screen (TM 5-3820-

c. Cleaning, Inspection, and Repair. Clean and

205-10/1).

inspect all parts. Repair or replace a damaged part as

necessary.

(2) Remove the vibrator screen support bars

and rubber deflectors from the unit as

d. Reassembly. Reassemble the lower screen

instructed on figure 101.

hopper illustrated on figure 105.

b. Cleaning, Inspection, and Repair. Clean and

e. Installation. Install the lower screen hopper on

inspect all parts. Replace or repair a defective or

the unit in reverse of the instructions on figure 104.

damaged part.

c. Installation.

170. Rubber Mountings and Deflectors

(1) Install the vibrator screen support bars

and rubber deflectors on the unit in

a. Removal.

reverse of the instructions on figure 101.

(1) Remove the rubber mountings from the

unit as instructed on figure 106.

(2) Install the vibrator screen (TM 5-3820-

205-10/1).

(2) Remove the rubber deflectors from the

unit as instructed on figure 107.

167. Discharge Chute Assembly

a. Removal.

Remove the discharge chute

b. Cleaning and Inspection. Clean and inspect all

extension and liners from the unit as instructed on figure

123