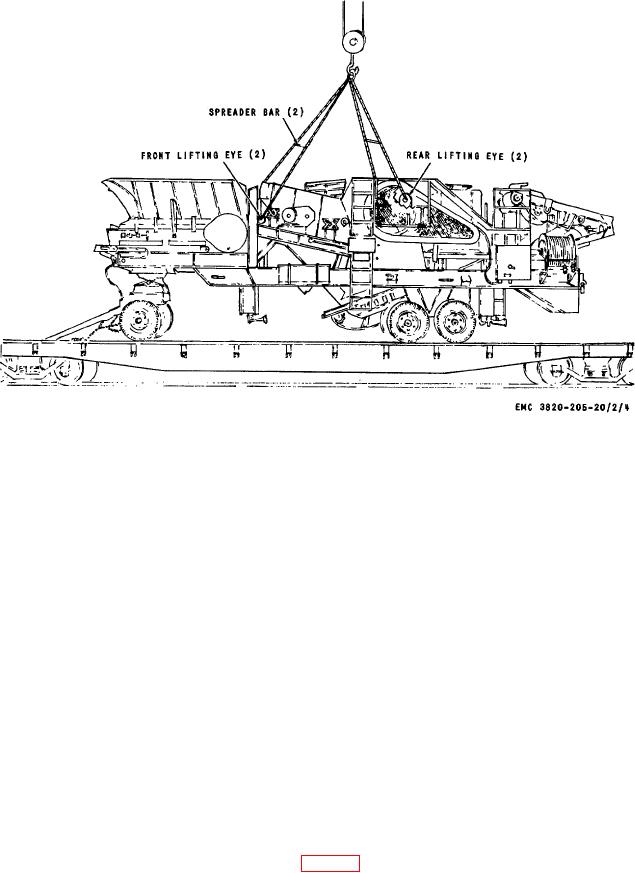

Figure 4. Unloading jaw crusher with lifting device.

(2)

Remove fire extinguisher and remaining items from the toolbox.

c.

Removal of Protective Material and Devices.

(1)

Remove protective tape from the taillights, meters, reflectors, instrument panel, muffler, electrical

terminals, air brake hose couplings and all taped openings on the engine.

(2)

Remove protective compound with an approved cleaning solvent.

8.

Inspection and Servicing the Jaw Crusher

a. Make a complete visual inspection to make sure the required tools, repair parts, and publications are with the

equipment (TM 5-3820-205-10/2).

b. Visually inspect the engine, motors and mounted components for missing parts or damage that may have

occured during loading, shipment, or unloading (TM 5-3820-205-10/2).

c. Inspect the wiring, fuel and oil lines, radiator and hoses, fuel tank, gages, and instruments and lights for

broken, loose, missing, or damaged parts (TM 5-3820-205-10/2).

d. Inspect drain plugs, breathers, fill caps, and draincocks to be sure they are secured and not leaking or

damaged (TM 5-3820-205-10/2).

e. Inspect tires, conveyor belts, airbrake hose and electrical leads for cuts, breaks, cracks, or signs of

deterioration. Correct or report any deficiencies noted and not corrected to field maintenance.

f.

Perform the preventive maintenance services (par. 20).

g. When the jaw crusher is received with new dry charge batteries and electrolyte packed separately, perform the

following services.

(1)

Remove battery box cover and fill caps (TM 543820-205-10/2).

(2)

Pour the electrolyte into each battery cell to a level of three-eighth inch above the plates.

AGO 8156A

9