CHAPTER 2

INSTALLATION AND OPERATING INSTRUCTIONS

Section I. SERVICE UPON RECEIPT OF EQUIPMENT

6.

Unloading the Jaw Crusher

a. Shipment by Rail. Due to its weight and overall dimensions, the primary method of transporting the jaw

crusher long distances will be by railroad. If moved over the highway it would normally be towed.

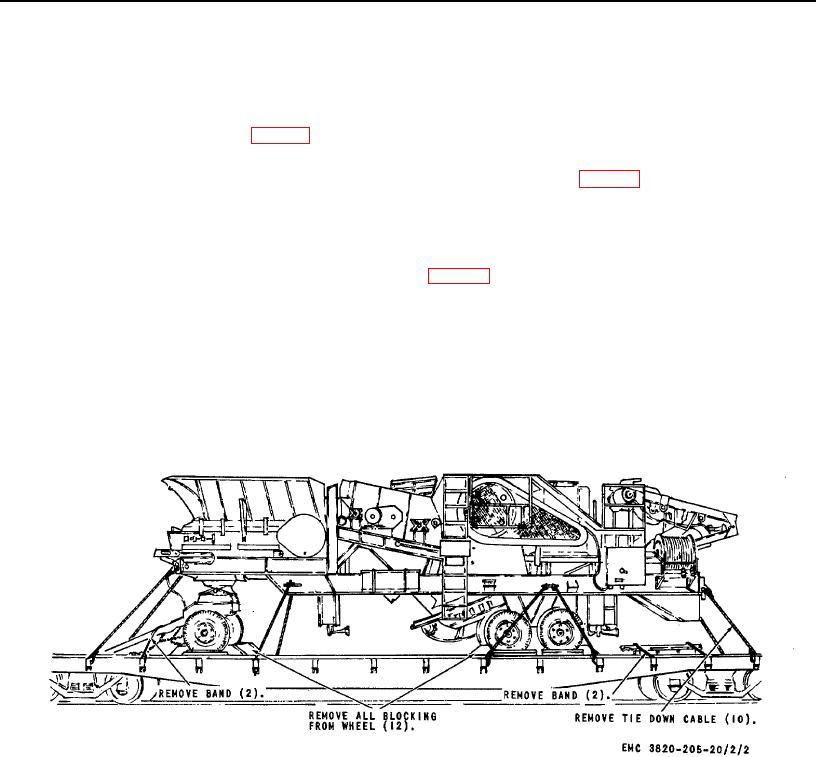

(1) Blocking and tiedown removal. Remove the blocking, and tiedown cables and straps that secure the jaw

crusher to the flatcar as illustrated on figure 2.

(2) Ramp unloading. The preferred method of unloading the jaw crusher is to tow it off the flatcar and down a

ramp. If a suitable ramp is not available, construct an unloading ramp as illustrated on figure 3;

Note. Secure the flatcar wheels, both front and rear, with 6 by 6 timber blocks.

(3)

Use a suitable towing vehicle and tow the jaw crusher from the flatcar.

b. Lifting the Jaw Crusher. If suitable lifting or hoisting equipment is available, attach the lifting slings and

equipment to the lifting eyes on the jaw crusher as illustrated on figure 4 and lift the crusher from the flatcar.

Warning: The lifting device must have the capacity for safely lifting and lowering 36 tons.

7.

Unpacking the Jaw Crusher

a. Depreservation. Prepare jaw crusher for inspection and operation as outlined on DA Form 2258, attached on

or near the operational controls.

b.

Unpacking.

(1)

Remove battery electrolyte and cables from the toolbox.

Figure 2. Blocking and tiedown, removal.

AGO 8156A

7