26. Hydraulic Cylinder Fails to Operate

Probable cause

Possible remedy

Leaking hydraulic lines................................................................Repair or replace hydraulic lines (pars. 133-135).

Seals or packing rings defective .................................................Replace seals and packing (pars. 133-135).

Hydraulic cylinder damaged .......................................................Repair or replace cylinder (pars. 133-135).

27. Jaw Crusher Fails to Operate

Probable cause

Possible remedy

Toggle plate broken ...................................................................Replace toggle plate (pars. 161-163).

Adjusting screws sheared or stripped ..........................................Replace adjusting screws (pars. 165-167).

28. Airbrakes Fail to Operate

Probable cause

Possible remedy

Air relay valve defective .............................................................Repair or replace air relay valve (pars. 200-202).

Air chambers defective ..............................................................Repair or replace air chambers (pars. 203-205).

Section III. REMOVAL AND INSTALLATION OF MAJOR COMPONENTS

OR AUXILIARIES

29. General

This section provides the necessary information to field

and depot maintenance personnel for the removal and

installation of the engine, pan feeder, scalper vibrating

screen, crusher, discharge conveyor, and the. bogie and

rear axle assemblies.

These assemblies may be

removed as an assembly for replacement or for major

repair to the Eagle Jaw Crusher Model 5157.

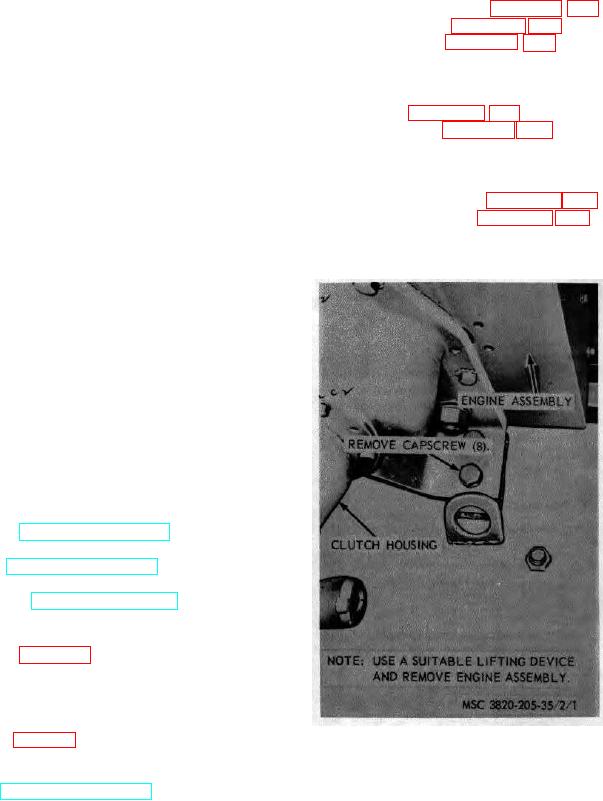

30. Engine Assembly

a.

Removal.

(1)

Loosen the tension on the drive belts

on the engine sheaves and remove

the belts (TM 5-3820-205-20/2).

(2)

Disconnect the battery lead from the

engine (TM 5-3820-205-20/2).

(3)

Disconnect the fuel supply lines from

the engine (TM 53820-205-20/2).

(4)

Remove the drive belt guards (TM 5-

382205-20/2).

(5)

Refer to figure 1 and remove the

engine.

b.

Installation.

(1)

Refer to figure 1 and install the engine

Figure 1. Engine assembly, removal and installation

on the unit.

(2)

Connect the fuel supply line to the

engine TM 5-3820-205-20/2).

AGO 8456A

17